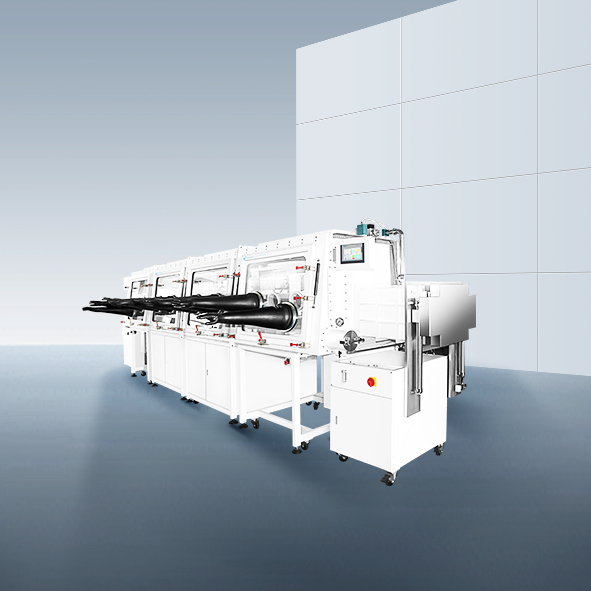

Solid state battery R&D production line

It can meet the needs of evaluation and screening of solid-state battery materials as well as development and testing of finished battery cells

It can be used to verify the process of converting the electrolyte from liquid to semi-solid and finally achieving all-solid state;

Meet the requirements for verification and performance testing of solid-state batteries of various systems such as polymers, oxides and sulfides as well as the preparation of metal lithium batteries.

The Solid State Battery R&D Production Line from Mikrouna is specifically engineered for forward-looking research and small-scale production of advanced solid-state batteries. This versatile line enables full-process experimentation and process verification—from the transformation of liquid electrolytes to semi-solid and ultimately all-solid-state electrolytes. It provides a reliable and controlled environment for testing and optimizing next-generation battery chemistries.

This production line is suitable for validating and preparing solid-state batteries of various systems, including polymer-based, oxide-based, and sulfide-based solid electrolytes, as well as for the development of lithium metal batteries. It offers flexible configuration and system integration tailored to the specific needs of R&D institutions and pilot-scale manufacturers, accelerating innovation and commercialization of solid-state battery technologies.

Key Features:

-

Supports process conversion verification from liquid to all-solid-state electrolyte systems

-

Compatible with multiple electrolyte systems: polymer, oxide, sulfide

-

Enables R&D and performance validation of lithium metal and solid-state batteries

-

High safety and environmental control standards for sensitive materials

-

Customizable modules to meet diverse research workflows and test parameters

-

Designed for small-scale pilot production and scalable experimentation

About Mikrouna

The Mikrouna lithium battery equipment team specializes in delivering full-process intelligent equipment solutions, including:

-

Pilot line systems for various solid-state battery technologies

-

Integrated solutions for lithium metal battery manufacturing

-

Advanced equipment for dry electrode preparation and lithium metal anode material development

-

Modular systems supporting the transition from R&D to mass production

With extensive experience in battery R&D automation, Mikrouna is committed to enabling innovation across the next generation of battery technologies through robust, customizable, and intelligent equipment solutions.

Related products

-

Quick View

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

-

Quick View

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m -

Quick View

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

Quick View

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

Reviews

There are no reviews yet.