ATLAS COPCO 1621304400 PIPE ZR/ZT

We are ATLAS COPCO 1621304400 PIPE ZR/ZT supplier and provide replacement parts for major air compressor manufacturers. Please feel free to contact us at henry.guan@foxmail.com with any questions of t

The ATLAS COPCO 1621304400 PIPE ZR/ZT-RUNGO is a top-of-the-line product designed for maximum efficiency and performance. This pipe is the perfect solution for all your pneumatic needs, offering unparalleled durability and reliability.

Manufactured by ATLAS COPCO, a leading brand in the industry, the 1621304400 PIPE ZR/ZT-RUNGO is built to last. It is made from high-quality materials that can withstand even the toughest working conditions. The pipe is designed to provide optimal airflow, reducing energy consumption and increasing the overall efficiency of your pneumatic system.

The ATLAS COPCO 1621304400 PIPE ZR/ZT-RUNGO is compatible with a wide range of pneumatic tools and machinery. It is easy to install and requires minimal maintenance, making it a cost-effective solution for all your pneumatic needs. The pipe is also lightweight and easy to handle, making it ideal for use in a variety of applications.

Related products

-

Quick View

Displacement Sensors

Contact UsDifferential Transformer Displacement Sensors (LVDTs) can be widely used in various industries of the national economy, such as aerospace, machinery, construction, textiles, railways, coal, metallurgy

-

Quick View

High Precision Machining Automotive Precision Parts

Contact UsWuxi Okin Hydraulic Machinery Co., Ltd. is located in Cangxia Industrial Park, Dongting Town, Xishan District, Wuxi City, covering an area of 6,000 square meters, adjacent to Wuxi East Railway Station

-

Quick View

DIN-EN 856 4SH

Contact UsSTANDARD: EN856 4SH MT98 4SH

COVER: oil resistant neoprene

REINFORCEMENT: four spiral high strength copper-coated steel wire

COVER; friction & weather resistant special rubber

TEMPERATURE RANGE: -40℃ /+100℃ ; -40 °F/+212°F LT-55 & HT150℃ customizable

APPLICATION: suitable for oil and water based fluid hydraulic system, construction machinery, agricultural machinery, oil drilling, mining machinery, iron and steel, chemical industry, energy, rail transit, food processing machinery and shipbuilding -

Quick View

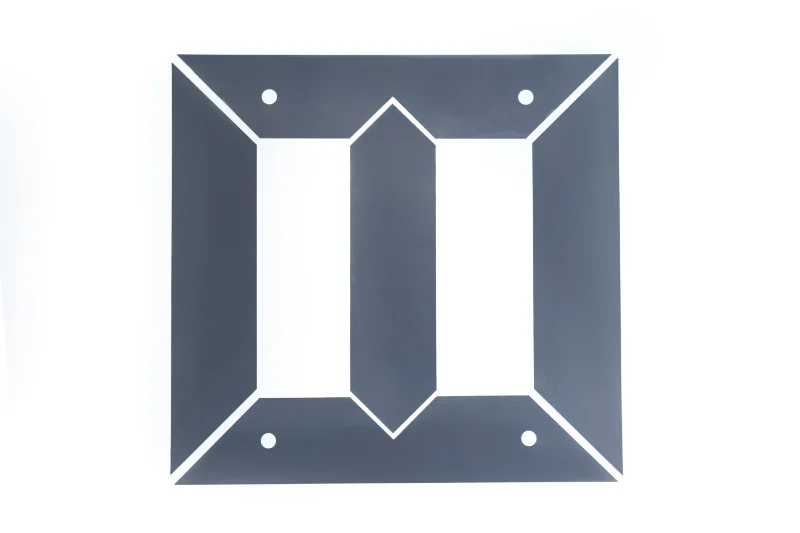

Oblique Cut Lamination

Contact UsShearing is a common cutting method for silicon steel sheets. Silicon steel is sheared with a carbide blade, which can cut the required size and shape. Shear method on the thermal impact of silicon steel core is small, the kerf is smoother, but the shear force is more damage, easy to produce deformation and burr. Therefore, the shear method is suitable for cutting smaller lamination, the requirement of surface flatness is not too high occasions.

Our company has introduced advanced oblique cut equipment, which is able to cut large silicon steel core to meet more needs of customers.

Reviews

There are no reviews yet.