Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

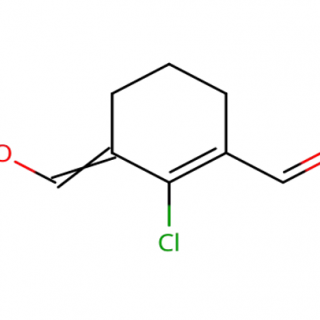

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

High Precision Machining Automotive Precision Parts

Wuxi Okin Hydraulic Machinery Co., Ltd. is located in Cangxia Industrial Park, Dongting Town, Xishan District, Wuxi City, covering an area of 6,000 square meters, adjacent to Wuxi East Railway Station

Advantages of High Precision Machining Automotive Precision Parts

– Superior Accuracy: Ensures tight tolerances and exact specifications for automotive applications.

– Enhanced Durability: High-quality materials and precise engineering result in long-lasting components.

– Improved Performance: Precision machining enhances functionality, reducing friction and wear.

– Cost Efficiency: Reduces material waste and minimizes errors, leading to lower production costs.

– Consistency & Reliability: Ensures uniform quality across large production batches.

Key Features of High Precision Machining Automotive Precision Parts

– Micron-Level Precision: Achieves ultra-fine tolerances suitable for critical automotive components.

– CNC Machining Technology: Utilizes advanced CNC systems for consistent and automated precision.

– Versatile Material Compatibility: Works with aluminum, stainless steel, titanium, and more.

– Complex Geometries: Capable of intricate shapes and designs tailored to automotive needs.

– High Surface Finish Quality: Achieves smooth, polished surfaces to enhance performance.

– Customization Options: Adaptable to various automotive applications, including engine, transmission, and suspension parts.

Manufacturing Process of High Precision Machining Automotive Precision Parts

– Material Selection: Choosing high-quality metals or alloys suited for automotive applications.

– CNC Programming: Developing precise machining codes for automated cutting and shaping.

– Precision Machining: Using multi-axis CNC machines for drilling, milling, turning, and grinding.

– Quality Control & Inspection: Utilizing CMM (Coordinate Measuring Machines) and laser scanning to verify dimensions.

– Surface Treatment: Applying coatings, anodizing, or polishing for corrosion resistance and durability.

– Final Assembly & Testing: Ensuring components meet automotive industry standards before delivery.

As one of high precision automotive parts machining service manufacturers, Wuxi Okin has the ability to design and manufacture with automated intelligent equipment.

Related products

-

Quick View

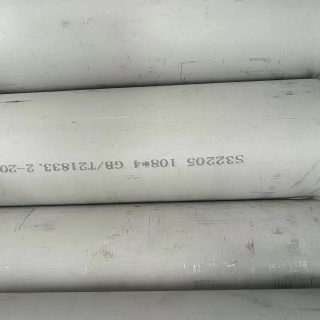

Duplex S32205 Seamless Pipe ASTM A790 Annealed Pickled

Contact UsSpecification: ASTM A790/A790M

Name: Duplex SS S32205 Seamless Pipe

Grade:S32205

Process: Seamless

Delivery Condiction:

1. Annealed, Pickled

2. Bright Annealed -

Quick View

DIN-EN 856 4SH

Contact UsSTANDARD: EN856 4SH MT98 4SH

COVER: oil resistant neoprene

REINFORCEMENT: four spiral high strength copper-coated steel wire

COVER; friction & weather resistant special rubber

TEMPERATURE RANGE: -40℃ /+100℃ ; -40 °F/+212°F LT-55 & HT150℃ customizable

APPLICATION: suitable for oil and water based fluid hydraulic system, construction machinery, agricultural machinery, oil drilling, mining machinery, iron and steel, chemical industry, energy, rail transit, food processing machinery and shipbuilding -

Quick View

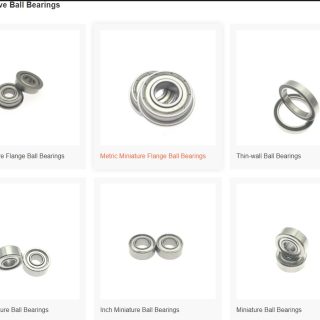

Deep Groove Ball Bearings

Contact UsDeep groove bearings are a widely used bearing type known for their simple design and excellent performance.

-

Quick View

Custom New Energy Harness

Contact UsWe mainly produce wiring harness products such as: Automotive Wiring Harnesses; New Energy Wiring Harnesses; Medical Machinery Wiring Harness; Home Appliance Wiring Harnesses as well as Auto Connectors/Terminals etc.

Reviews

There are no reviews yet.