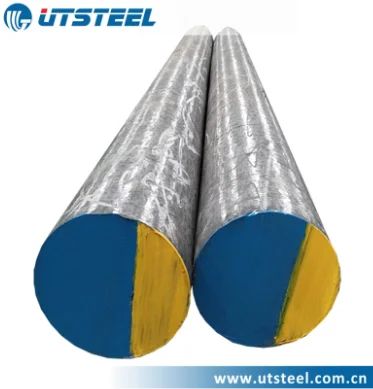

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

https://www.gcmicgroup.com/UT-6523-8620-20CrNiMoA-Cold-Drawn-Bar-Cold-Drawn-Bar-Alloy-Steel.html

UT 1.6523/8620/20CrNiMoA Alloy Structural Steel has High hardenability, no tempering brittleness, good weldability, little tendency to form cold crack, good machinability and cold strain plasticity.

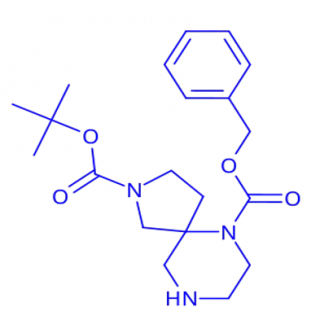

| Steel Grade | 1.6523/8620/20CrNiMoA |

| Dimension | Diameter Ø10-1000mm |

| Delivery Condition | HB≤197 |

| Surface Treatment | Black Surface / Roughed Machined Surface / Turned Surface |

| Production Condition | |

| Stock Quantity | 1000 tons |

| Ultrasonic Test | Sep1921-84 D/D or E/e Under 100% Test |

| MOQ | 10 tonnes |

| Mill Sheet Certificate | Provided |

| HS Code | Hot Rolled:722830 Forged: 722840 |

| Technique | Hot Rolled / Forged |

| Lead Time | 7-10 days |

| Trademark | UTSTEEL |

Chemical Composition(%)

| C | Si | Mn | Cr | S | P | Mo | V | Ni | W |

| 0.17-0.23 | 0.17-0.37 | 0.60-0.95 | 0.40-0.70 | ≤0.03 | ≤0.03 | 0.20-0.30 | / | 0.25-0.75 | / |

Application

UT 1.6523/8620/20CrNiMoA Alloy Structural Steel is normally used in the manufacturing of small and medium-sized automobiles and tractors' engines and gears in the transmission system. It can also replace 12CrNi3 steel to produce carburized parts and cyanide parts with high core performance requirement, such as tooth claws, toothwheel bodies for oil drilling and metallurgical open-pit mine.

Related products

-

Quick View

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m -

Quick View

MA-(2~8MM)×1800MM Steel Coil Slitting Line

Contact UsMA-(2~8MM)×1800MM Steel Coil Slitting Line is mainly composed by the following components : uncoiler, guiding device

-

Quick View

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

-

Quick View

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

Reviews

There are no reviews yet.