Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

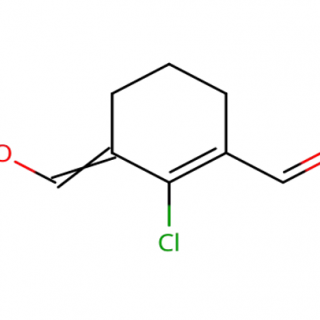

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

VMC 700 CNC Vertical Milling Center

The three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

https://www.josencnc.com/VMC-700-CNC-Vertical-Machining-Center.html

The machine is suitable for communication, medical equipment, power tools, 3C products processing and other fields. The three axes are designed with direct drive to ensure the stability of high precision and high speed displacement. High inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds. The standard 21 servo tool changer is equipped with fast, simple and long life characteristics.

1.This model is suitable for communication, medical equipment, power tools, automation parts, 3C products processing.

2.The main features of the machine are compact and flexible, fast displacement speed, high spindle speed, fast drilling and tapping, fast tool change, mainly used for processing light and small metals, not suitable for heavy cutting.

3.The three axes use ball screw and linear guide imported from Taiwan, with high rigidity, low noise, low friction and high sensitivity, which can improve the processing speed and accuracy.

4.Spindle short nose end design, the spindle motor transmission power to the maximum, cutting rigidity is excellent, improve the machining accuracy and extend the service life of the spindle.

5.The fully enclosed guard keeps smooth and low noise when moving at high speed, and isolates the chip liquid and chips to the greatest extent, so that the maintenance and service life of the wire rail and screw can reach the best state.

6.Z-axis is designed without counterweight, and the power of servo motor is deployed and the driving function of z-axis is improved to achieve high speed and the best surface finish of the product.

| ITEM | UNIT | TV-700 |

| Travel | ||

| X-axis travel | mm | 700 |

| Y-axis travel | mm | 400 |

| Z-axis travel | mm | 350 |

| Worktable size | ||

| Working table size (X*Y) | mm | 850×400 |

| Max.loading capacity of working table | kg | 250 |

| Table T-slot size (width * number of slots * spacing) | number | 14x3x125 |

| Spindle | ||

| Spindle speed | rpm | 20000 |

| Spindle drive form | Direct driven | |

| Spindle power | kW | 3.7/5.5 |

| Spindle bore specification | BT30 | |

| Distance from spindle to table surface | mm | 150-500 |

| Spindle feed | ||

| Rapid feed rate(X,Y,Z) | m/min | 48/48/48 |

| Cutting feed rate | mm/min | 10000 |

| Tool magazine(Optional) | ||

| Tool magazine capacity | arm type 21 | |

| Tool diameter/adjacent tool space | mm | Φ80/Φ80 |

| Max. Tool length | mm | 200 |

| Max. Tool weight | kg | 3 |

| Accuracy | ||

| Positioning accuracy | mm | ±0.005 |

| Reproduction accuracy | mm | ±0.003 |

| Others | ||

| Controller | kg/cm² | 0i-MF/M80 |

| Air pressure demand | kg/cm2 | 6 |

| Power demand | kVA | 20 |

| Machine weight | T | 3.2 |

| Model | A | D | E | F | G |

| TV-700 | 2050 | 2270 | 2270 | 2100 | 350 |

|

|||||

| Model | A | B | C | D | E | F | G | H | I | J | K | T |

| TV-700 | 850 | 400 | 75 | 125 | 125 | – | – | 14 | 25 | 10 | 24 | 3 |

|

||||||||||||

Related products

-

Quick View

RO water Treatment

Contact UsThe reverse osmosis equipment passes the raw water through fine filters, granular activated carbon filters, compressed activated carbon filters, etc., and then pressurizes it through a pump, using a p

-

Quick View

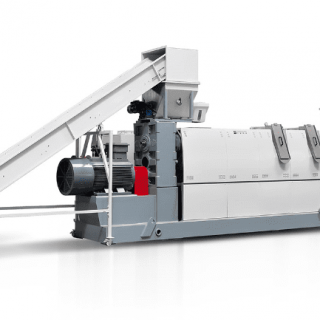

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

Quick View

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

-

Quick View

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

Reviews

There are no reviews yet.