Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

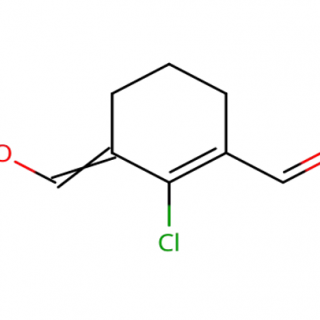

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

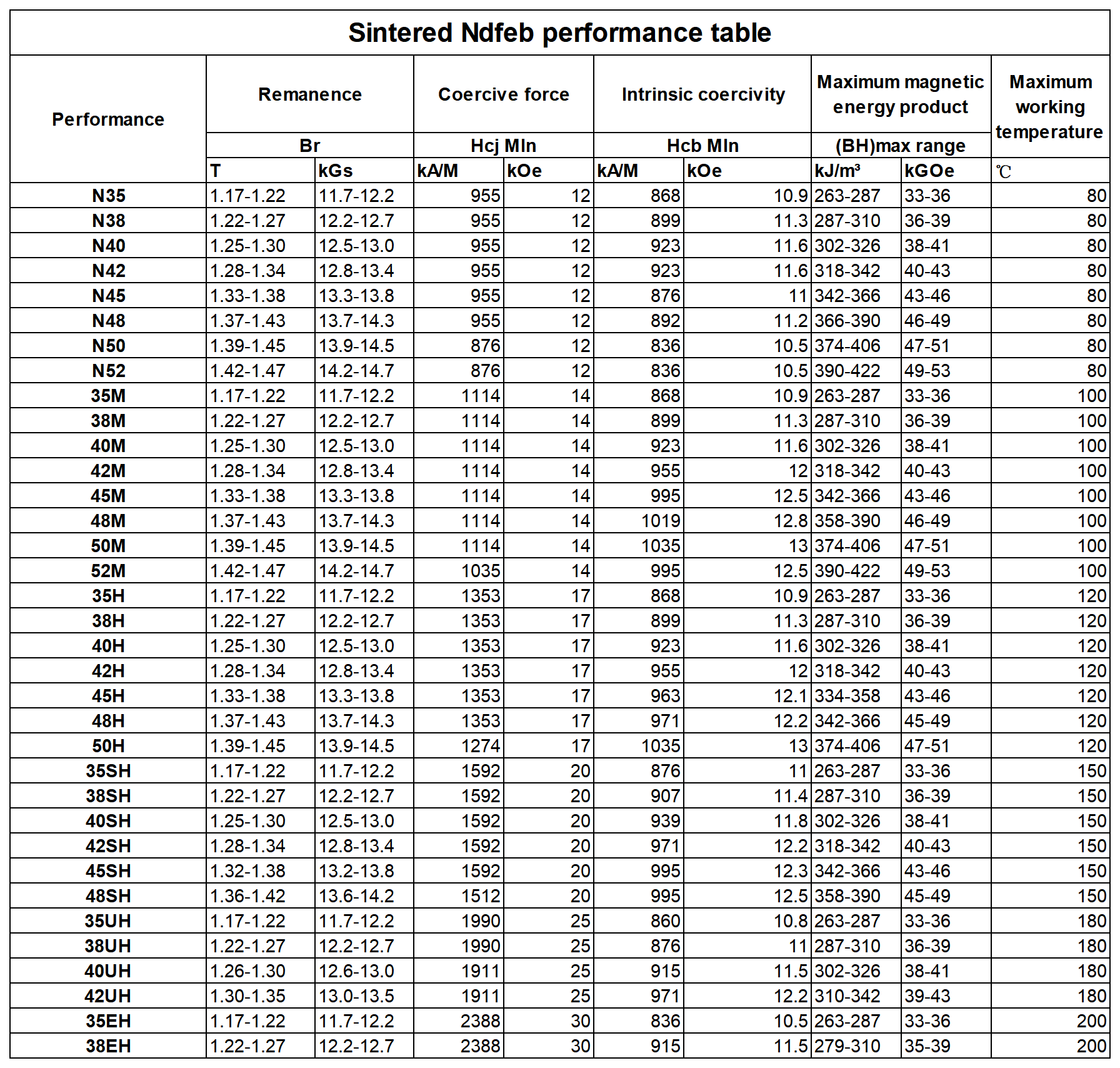

Customized Strong magnet de-ironing separator, N35-N52 grade

Size: diameter from 1.5-70mm, length from 0.5-100mm. The magnet grade is at least N35.

Information in need: The magnet and the stainless steel grade, size, surface treatment, magnetizing direction, the quantity. Especially when the magnetic force and the temperature are in specific need.

https://www.cnysckj.com/Customized-Strong-magnet-de-ironing-separator-N35-N52-grade.html

Size: diameter from 1.5-70mm, length from 0.5-100mm. The magnet grade is at

least N35.

Information in need: The magnet and the stainless steel grade, size, surface

treatment, magnetizing direction, the quantity. Especially when the magnetic

force and the temperature are in specific need.

Aging treatment: at most two days when the details received, then about 15-20

days in production.

Package: carton, the carton size is 340mm x 260mm x 170mm

Payment: L/C, T/T, Paypal

Transportation: by shipment, express or air

Surface treatment: Nickel, Zinc or epoxy.

Made by your drawing.

We also have three oversea locations in Europe, as the follows pictures show.

N35 N52 grade strong magnet deironing separator is a highly efficient magnetic separation equipment, designed for removing iron impurities from materials.

Product advantages and features:

1. High magnetic field strength: using N35-N52 grade rare earth permanent magnet materials, providing strong attraction and effectively separating iron impurities.

2. Customized service: providing customized solutions according to the specific needs of customers to meet the requirements of different materials and processes.

3. Durability: using high-quality materials and advanced manufacturing processes to ensure the long-term stable operation of the equipment.

Core competencies:

1. Technological innovation: continuous research and development of new technologies to improve the performance and efficiency of strong magnet de-ironing separator.

2. Quality assurance: strict quality control process to ensure that each equipment meets high standards.

Mainly application:

1. Food processing: ensure food safety and remove metal impurities that may affect product quality.

2. Chemical industry: remove iron from raw materials and products to improve product purity.

3. Pharmaceutical industry: ensure the purity of drugs and avoid metal contamination.

4. Plastic recycling: remove metal impurities from plastic particles and improve the quality of recycled materials.

Manufacturing process and design:

1. Precision manufacturing: use precision manufacturing technology to ensure that each component of the equipment meets the design requirements.

2. Humanized design: considering the convenience of operation and the simplicity of maintenance, the equipment design is easy to use and maintain.

3. Rotary design: some models adopt rotating magnetic de-ironing separator design to improve separation efficiency and processing capacity.

Company strength:

1. Professional team: have an experienced technical team dedicated to continuous improvement and innovation of products.

2. Global service: provide a global sales and service network to ensure that customers can get timely support.

FAQ

Q1: What safety precautions should be taken when operating a strong magnet de-ironing separator?

A: Avoid placing ferromagnetic objects near it to prevent accidental attraction and ensure proper grounding.

Q2: What are the customized services of Customized strong magnet de-ironing separator?

A: We can customize the magnetic field strength, equipment size and separation method according to your material characteristics, processing volume and process requirements.

Q3: What is the difference between N35-N52 grade strong magnet?

A: N35 to N52 represent the grade of the magnet. The larger the number, the higher the magnetic field strength. You can choose the appropriate magnet grade according to the separation requirements.

Q4: What are the maintenance requirements for the De-ironing separator?

A: Check the equipment regularly, clean the surface of the magnet, and ensure that there is no material residue to maintain optimal performance.

Q5: What are the advantages of Rotating magnetic de-ironing separator?

A: The rotating design can improve the fluidity of the material, reduce the risk of blockage, and improve separation efficiency.

Related products

-

Quick View

310S Stainless Steel Plate

Contact Us● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month;

● Payment terms L/C, T/T;

● It can pack by container or bulk vessel.

● Standard export seaworthy package, it use steel belt with bundle according product’s size.

● We can make it as your requirement. -

Quick View

304L Stainless Steel Coil

Contact Us304L stainless steel is remarkably similar to 304 stainless steel in their chemical composition with one key difference.

-

Quick View

1070 Aluminum Plate

Contact Us1070 belongs to the pure aluminum series alloys. The aluminum content is greater than 99.7%, and the content of other impurity elements is low.

-

Quick View

310S Stainless Steel Strip

Contact Us310S stainless steel is austenitic chromium-nickel stainless steel, with good oxidation resistance, corrosion resistance

Reviews

There are no reviews yet.