Automatic Pulp Molded Meal Bag Production Line

In recent years, the global plastic limit, plastic ban and dual carbon sustainable development policies have beencontinuously promoted, bringing huge development opportunities…

ParameterParameter

Outer dimension(mm): L3100*W2160*H3800mm

Platen size(mm): 800*650 mm

Equipment weight:2.0T

Forming method:Reciprocating

Max. product height:80-100mm

Pulp feeding style:Continuous supply of slurry

Drying method:Drying outside the mold

Product transfer method: Wet embryo transfer method

Power mode:Cylinder

Material receiving method:Pneumatic lifting platform

Number of work stations:2 positions

Capacity:Related to product shape and labor efficiency

Cycle time:8-16 seconds/drop

Related products

-

Quick View

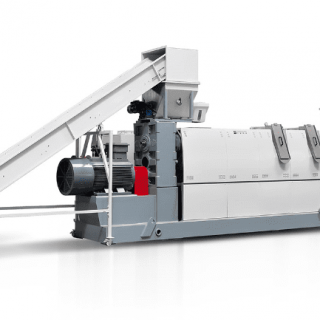

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

Quick View

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

Quick View

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

Reviews

There are no reviews yet.