Category

Popular

-

FZKJ-RE-1:20ft Refrigerated Container+PV+Energy Storage System

FZKJ-RE-1:20ft Refrigerated Container+PV+Energy Storage System

-

Women Hoodies Long Sleeve Kangaroo Pocket Pullover Trendy Basic Oversized Sweatshirts

Women Hoodies Long Sleeve Kangaroo Pocket Pullover Trendy Basic Oversized Sweatshirts

-

Ecomotor-R140E Brushed DC Micro Motor(Toy)

Ecomotor-R140E Brushed DC Micro Motor(Toy)

-

Axial type roof fans

Axial type roof fans

-

Hison 4 Stroke Jet Engine Powered New Fiberglass kayak for Fishing Jet Engine Powered Kayak

Hison 4 Stroke Jet Engine Powered New Fiberglass kayak for Fishing Jet Engine Powered Kayak

Small-scale Waste Incinerator

Solid furnace can be classified into vertical and horizontal types, and furnace structure can be categorized as water-cooled wall and refractory mud pouring type.

Ⅰ. Introduction of the Small-scale Waste Incinerator:

Solid furnaces can be categorized into vertical and horizontal designs, with their structures differentiated primarily by two types: water-cooled wall constructions and refractory concrete casting. Water-cooled wall furnaces are typically employed for high-calorific-value waste, whereas refractory concrete is better suited for waste with lower calorific values. Fixed furnaces, also known as manually operated furnaces, conventionally involve manual feeding and ash removal processes, although they can be customized with automated feed and discharge systems based on waste characteristics and customer needs.

The decision to incorporate a grate within a solid furnace is contingent upon the physical form and composition of the material being processed. Additionally, these furnaces feature cooling ash hoppers and bottom oxygen supplementation systems to enhance combustion efficiency.

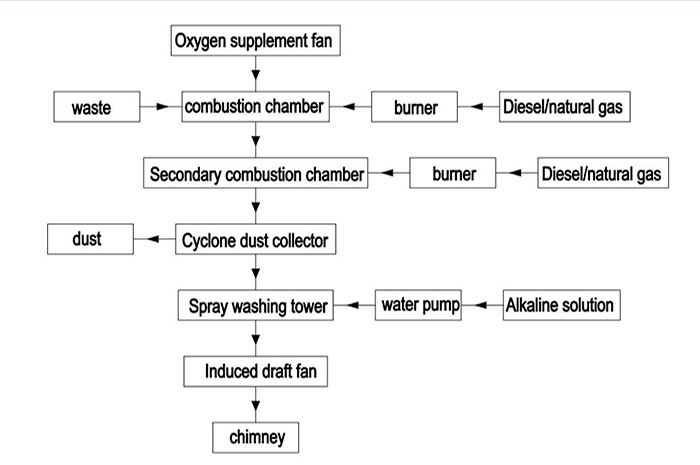

In remote mountainous areas where centralized waste management is impractical, and for immediate on-site disposal needs such as the incineration of animal carcasses, fixed furnaces adopt advanced incineration technologies and equipment to handle a variety of waste streams, including municipal solid waste. These furnaces are also equipped with sophisticated exhaust gas treatment systems that target post-combustion pollutants, ensuring emissions comply with national standards and prevent secondary pollution. Furthermore, they facilitate the recovery of substantial amounts of hot water, warm air, and steam, which can be utilized for both residential and industrial purposes, thereby contributing to energy recycling and sustainability.

Ⅱ. Processing objects:

Industrial Hazardous Waste (Solid, Liquid), Sludge, and General Municipal Solid Waste.

Handling Capacity: 20-400 kg/hour.

Ⅲ. Technical advantages:

1. The furnace features a large internal volume, high furnace load capacity, ample operational flexibility, and a broad, stable range of applications.

2. Designed for negative pressure combustion to prevent backfire and ensure no harmful gases escape, ensuring safe and reliable operation.

3. Equipped with agitation ports, ash discharge outlets, and a furnace grate drying mechanism.

4. Incorporates a unique supplementary oxygen supply system to ensure high combustion efficiency.

5. Auxiliary combustion systems and vital components employ imported parts, ensuring long-term, reliable operation of the equipment.

6. Advanced automatic control technology guarantees the safe and reliable operation of the equipment.

7. Employing a comprehensive and rational exhaust gas treatment and purification system to ensure compliance with environmental emission standards.

Related products

-

Quick View

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

Quick View

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

-

Quick View

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

Quick View

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

Reviews

There are no reviews yet.