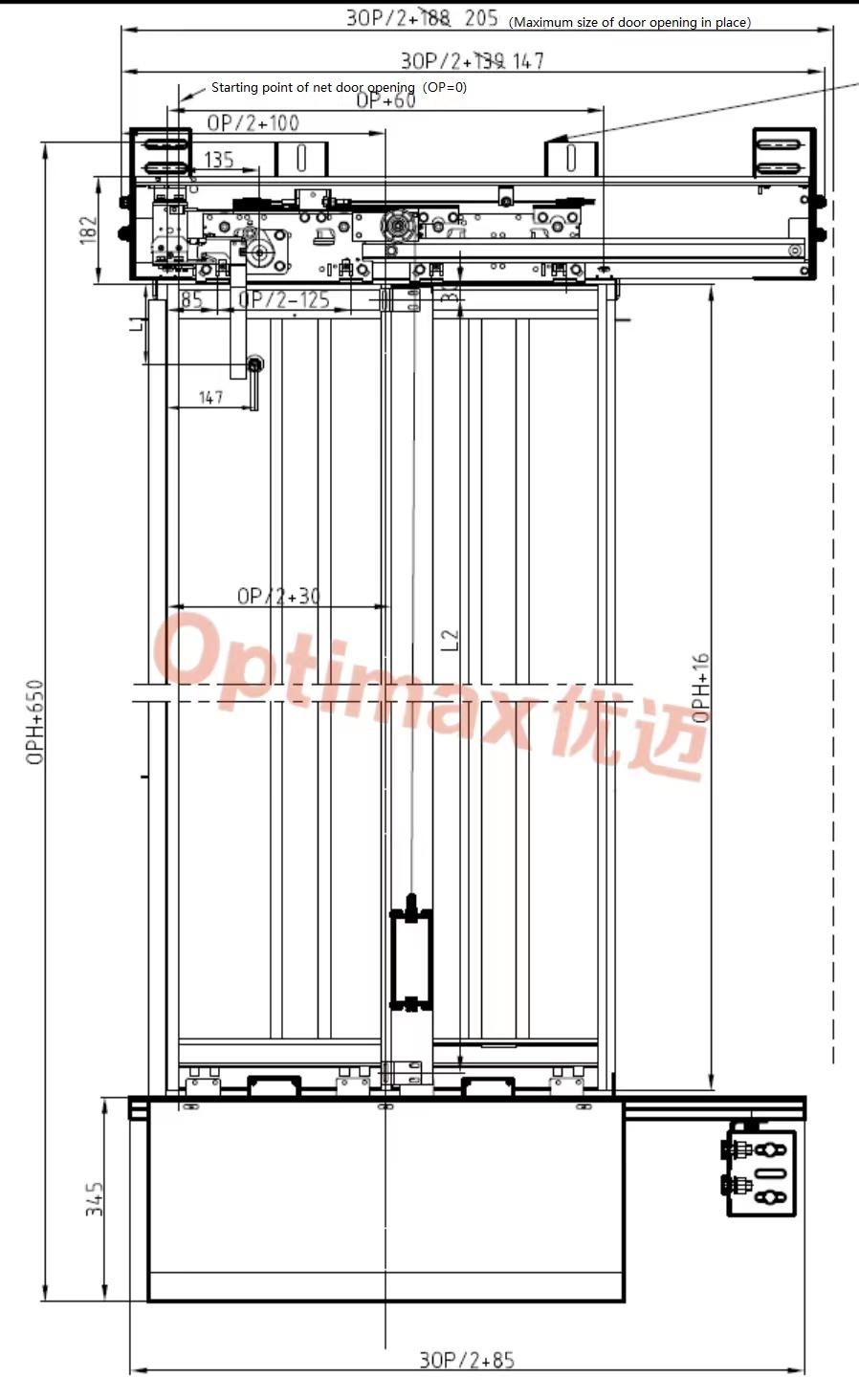

LD-2S96A-O Side Open Landing Door System

The LD-2S96A-O Side Open Landing Door System features a robust 96-mm sill design,it guarantees structural strength and stability,ensuring smooth, safe and quiet operation for passenger entry and exit.

https://www.xizi-ec.com/LD-2S96A-O-Side-Open-Landing-Door-System-with-96-sill.html

Opening type:Side Open Two Panel

Self-closing Type:Heavy hammer autistic

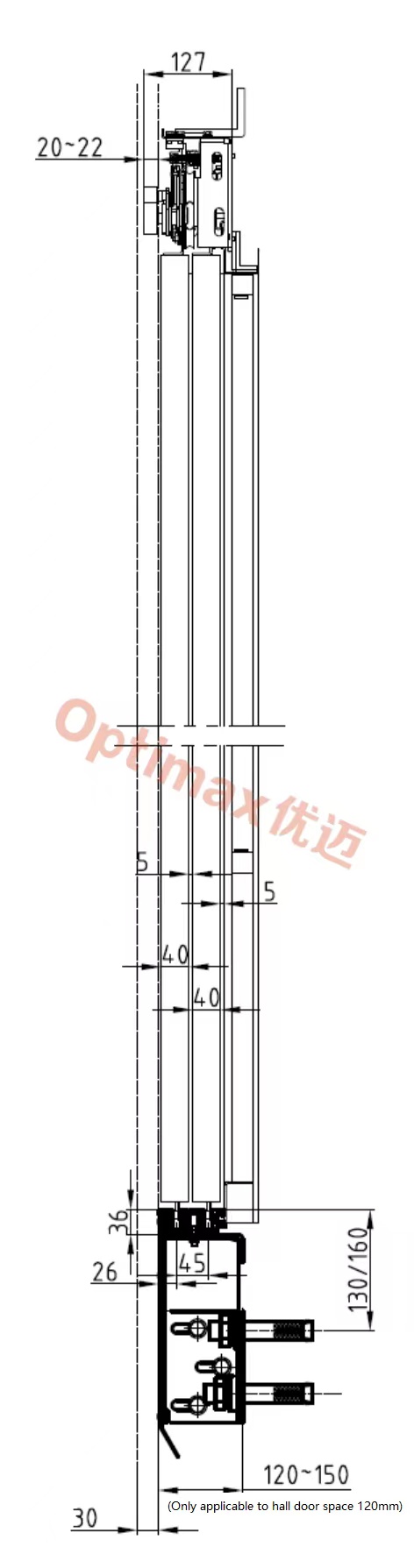

Sill Width:96mm

Hall Door Space:120mm

Speed: Maximum 2m/s

Match The Door Panel Material: Steel Door

OP(mm):700-1800

OPH(mm):2000-2600

This product is designed, tested and manufactured in accordance with higher standards than conventional passengers elevators. Matching door panel thickness 1.2mm, optional 1.5mm. It has strong adaptability and matches various door operators and assembly line door panels of various manufacturers in the market. It has the advantages of compact structure, easy installation and debugging. The vulnerable parts are removable for convenient maintenance.

Data Sheet Unit:mm

|

OP(Clear Opening Width) |

700 |

750 |

800 |

850 |

900 |

950 |

1000 |

1050 |

1100 |

1150 |

1200 |

1250 |

1300 |

1350 |

1400 |

1450 |

1500 |

1550 |

1600 |

1650 |

1700 |

1750 |

1800 |

|

L1=3OP/2+188 |

1238 |

1313 |

1388 |

1463 |

1538 |

1613 |

1688 |

1763 |

1838 |

1913 |

1988 |

2063 |

2138 |

2213 |

2288 |

2363 |

2438 |

2513 |

2588 |

2663 |

2738 |

2813 |

2888 |

|

OPH |

2000~2600 |

||||||||||||||||||||||

Related products

-

Quick View

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

Quick View

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

Quick View

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

Reviews

There are no reviews yet.