Category

Popular

-

The Ultimate Guide to Choosing the Best Pink Rose Flower Bubble Machine Toy for Your Child’s Safety and Fun

The Ultimate Guide to Choosing the Best Pink Rose Flower Bubble Machine Toy for Your Child’s Safety and Fun

-

DOPRO Engine Storage Racks – Maximize Space, Protect Engines

DOPRO Engine Storage Racks – Maximize Space, Protect Engines

-

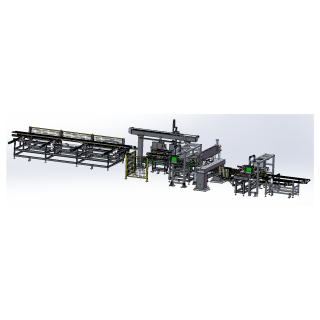

CLW-7000 automatic stamping production line of photovoltaic frame

CLW-7000 automatic stamping production line of photovoltaic frame

-

Full-Print Large Sublimation Summer Vibes Beach Tote Bag

Full-Print Large Sublimation Summer Vibes Beach Tote Bag

-

climbing and long-distance riding electric bicycle

climbing and long-distance riding electric bicycle

Milled carbon fiber for plastic reinforcement

Carbon fiber powder can enhance the mechanical, thermal, and functional properties of plastics by regulating the interface bonding and dispersion state.

Mechanical Reinforcement Mechanism

-

Load Transfer: After uniform dispersion, carbon fiber powder acts as a "rigid skeleton" to bear external loads and reduce the deformation of the plastic matrix. When the addition amount is 10%-20%, the tensile strength of the composite material can be increased by 50%-150%, and the flexural modulus can be increased by 100%-300%.

-

Inhibition of Crack Propagation: The high tear resistance of carbon fiber powder can block the spread of cracks in the plastic matrix and improve the impact resistance (for example, after adding 15% carbon fiber powder to PA6, the notched impact strength is increased by about 30%).

Improvement of Thermal Properties

Enhancement of Functionality

Engineering Plastics: PA (Nylon)

-

Application Scenarios: Automotive gears, bearing cages, high-pressure valve components.

-

Formula Design: Adding 10%-30% carbon fiber powder (particle size 5-15μm, surface amination treatment) can increase the tensile strength of PA6 from 75MPa to over 120MPa, while reducing water absorption (to minimize dimensional changes).

Special Engineering Plastics: PEEK

-

Application Scenarios: Aerospace structural parts, medical implants, high-temperature bearings.

-

Technical Points: The melting temperature of PEEK (343℃) is close to the oxidation temperature of carbon fibers. It is necessary to use carbon fiber powder with an anti-oxidation coating (such as nickel-plated or silicon-plated). When the addition amount is controlled at 15%-25%, the flexural modulus of PEEK can be increased from 3.8GPa to over 8GPa.

General Plastics: PP (Polypropylene)

-

Application Scenarios: Automotive bumpers, electronic device housings (with antistatic requirements).

-

<span style="-weBe the first to review “Milled carbon fiber for plastic reinforcement” Cancel reply

Related products

-

Quick View

PE Double-Wall Corrugated Pipe

Contact UsHDPE Double-Wall Corrugated Pipe is a lightweight, high-pressure resistant solution for sewage and drainage systems. Crafted from high-density polyethylene, it boasts a smooth inner wall and corrugated outer wall, ensuring durability and longevity. With its convenient and reliable connection, this innovative pipe replaces traditional concrete and cast iron alternatives. Ideal for various applications worldwide, it offers fast construction and cost savings, making it the preferred choice for modern infrastructure projects .

-

Quick View

Chopped glass fiber for friction materials

Contact UsAs an important reinforcing material, chopped glass fiber plays a vital role in friction materials.

-

Quick View

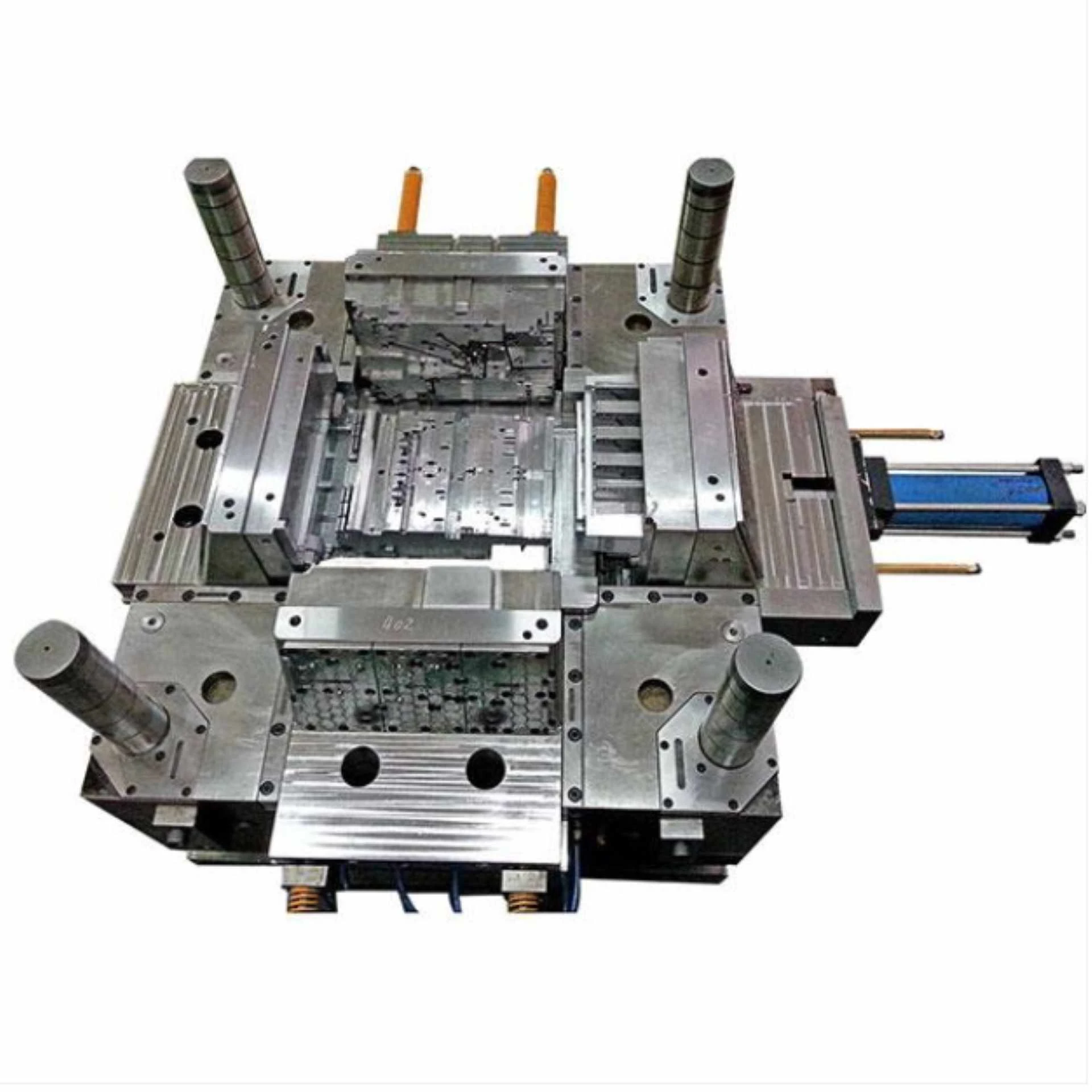

Composite Printer Metal Mold

Contact UsXuzhong Technology (Shenzhen) Co., Ltd. is located in Shenzhen, China, adjacent to Hong Kong. We are a company focusing on exporting mold business.

-

Quick View

Rubber Pad for Motor Mounts Rubber Shock Absorber anti-vibration | Vibration Transmission Rate <15%

Contact UsRubber Pad for Motor Mounts Rubber Shock Absorber anti-vibration | Vibration Transmission Rate <15%

Reviews

There are no reviews yet.