Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

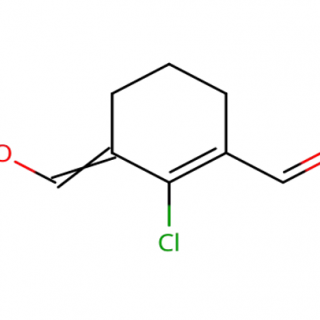

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

Conductive sheet PS

This conductive PS sheet has dust-proof effect, low cost, good conductive effect, excellent surface wear resistance and can be used in LCD tray, electronic component tray and IC tray packaging.

https://www.xrhpack.com/Conductive-sheet-PS.html

THIS TYPE SHEET is conductive, we can produce pet,ps,pp, can reach ESD 4-6. This product has dust-proof effect, low cost, good conductive effect, excellent surface wear resistance and can be used again. It can be used in packaging fields such as LCD trays, electronic component trays, and IC trays.

1. MOQ: 1000KG

2. Packing Method: Pallet

3. Resistance Value: 4-6

4. Thickness and Width: According to customer needs, samples can be provided.

5. Color: Transparent, White, Green, Black, etc. (According to Customer Needs)

6. Range: PET, PS, PP

High Efficient Conductive Performance of Conductive PS Sheet

Conductive PS Sheet, also known as conductive polystyrene sheet, is a specialized material designed to provide superior electrical conductivity, making it an essential component for various industrial applications. XRH, a reputable conductive PS sheet wholesale supplier, offers top-quality materials tailored to meet the specific needs of industries such as electronics, packaging, and automotive.

The core feature of a conductive PS sheet is its excellent electrical conductivity, which is achieved by adding conductive additives (such as carbon or metal particles) to the polystyrene matrix. This process enables the material to not only maintain the excellent characteristics of traditional polystyrene, such as lightweight, strong durability, and easy processing but also has the ability to eliminate static electricity and protect sensitive electronic components from electromagnetic interference (EMI). This material is particularly important in areas with high requirements for electrical conductivity

The conductive properties of conductive PS sheets have been rigorously tested and optimized to ensure that they perform well under various environmental conditions. Whether in an environment with high humidity or at extreme temperatures, the conductive PS sheet provided by XRH can maintain stable conductive properties. This makes it an ideal choice for electronic components, packaging materials, and other products that require protection from static electricity and electromagnetic interference.

The conductive properties of the conductive PS sheet come from its internal microstructure design. By evenly distributing conductive particles in the polystyrene matrix, a continuous conductive path is formed, ensuring that the material performs well in charge conduction and static dissipation. Such a design not only improves the conductive efficiency of the material but also ensures its mechanical strength and durability, enabling it to maintain stable performance after long-term use.

Anti-static Properties of Conductive PS Sheets

As a leading conductive PS sheet company, XRH provides excellent solutions in the field of electrostatic protection. With the development of science and technology and the increasing complexity of industrial production, the importance of electrostatic protection has become increasingly prominent. Especially in high-tech fields such as electronic products, semiconductors, and precision instruments, static electricity accumulation may cause product damage, performance degradation, and even safety accidents. XRH's conductive PS sheet provides reliable electrostatic protection for these industries with its excellent anti-static properties.

Conductive PS sheet is an important material in the field of electrostatic protection because of its excellent anti-static properties. Static electricity may bring many hidden dangers in industrial production, especially in the manufacturing and transportation of electronic products, where static electricity accumulation may cause component damage, data loss, and even fire and other safety accidents. The use of conductive PS sheet can effectively eliminate these hidden dangers and provide all-around electrostatic protection for production and logistics links.

The anti-static properties of the conductive PS sheet are mainly reflected in its excellent conductivity. By adding conductive substances to polystyrene materials, the material can quickly dissipate static charges and prevent static electricity from accumulating on the surface of the material. Compared with ordinary antistatic materials, conductive PS sheets can more effectively prevent static electricity accumulation and maintain a stable antistatic effect during long-term use. This continuous protection ability is particularly important in the packaging and protection of electronic components, ensuring that the product is protected from static electricity in all aspects of manufacturing, transportation, and storage.

In addition, conductive PS sheet also has good mechanical properties and processing properties. This material is not only durable and can withstand external pressure and impact, but also has excellent plasticity and can be processed into various shapes and sizes according to different application requirements. Therefore, conductive PS sheet not only performs well in the field of antistatic but can also be widely used in various complex industrial environments.

For those industries that require strict static control, a conductive PS sheet is an indispensable material. It not only provides continuous and stable antistatic protection but also takes into account a variety of application requirements. It is an ideal choice for achieving safe production and improving product quality. Whether it is when packaging sensitive electronic components or in production lines that require antistatic, conductive PS sheets can play an important role and provide companies with reliable static management solutions.

Superior Thermoforming Capability of PS Conductive Sheet Rolls

PS conductive sheet roll is widely recognized for its superior thermoforming capability. This material has good flexibility and plasticity when heated, and can easily adapt to the shapes of various complex molds, meeting the strict requirements of molding accuracy for different industrial applications. During the thermoforming process, PS conductive sheet roll exhibits excellent performance. First, it can soften quickly when heated and quickly set after cooling, ensuring the efficiency of the molding process. This feature greatly improves production efficiency and reduces production time and cost. Secondly, the products of PS conductive sheet roll after thermoforming have high dimensional stability and can maintain the desired shape without deformation, which is crucial to ensure the consistency and accuracy of the finished product. In addition, the material can still maintain its conductive properties and mechanical strength during the thermoforming process, ensuring the functionality and durability of the final product. Due to its excellent thermoforming capability, PS conductive sheet roll is widely used in the packaging and protection of electronic components, providing efficient electrostatic protection and mechanical protection. Whether it is used to produce precision electronic product trays or conductive separators with complex shapes, PS conductive sheet roll can provide excellent molding effects and performance guarantees. The thermoforming capability of this material makes it an ideal choice for industries such as electronics and electrical appliances.

The Role of Conductive PS Blister Sheet in the Packaging Field

In the development of modern industry and technology, the choice of packaging materials not only determines the safety of the product but also directly affects the company's cost, brand image and market competitiveness. Especially in high-precision industries such as electronic products, medical equipment, and auto parts, conductive PS blister sheet has become an irreplaceable material in the packaging field with its unique conductive properties, molding capabilities, mechanical strength, and environmental protection advantages.

Effective Electrostatic Protection

Static electricity has always been a serious hazard in the production and transportation of electronic components and precision instruments. Static electricity build-up and discharge can cause electronic components to short out, data loss, or even outright damage to highly sensitive equipment. The core advantage of the conductive PS blister sheet is its excellent electrical conductivity. This material effectively channels and neutralizes static build-up, minimizing the risk of static electricity. Compared with traditional packaging materials, the application of conductive PS blister sheet significantly reduces the product scrap rate caused by electrostatic discharge (ESD), ensuring the safety of electronic products from production to the hands of end users. This electrostatic protection capability makes it widely used in high-tech industries such as semiconductors, integrated circuits, and electronic components.

Excellent molding and Design Flexibility

The superior performance of conductive PS blister sheet in molding performance gives it great flexibility and adaptability in packaging design. Through the thermoforming process, this material can be made into blister packaging with various complex shapes to accurately match the size and shape of different products. Whether it is small and complex electronic components or larger precision instruments, conductive PS blister sheets can provide customized protection solutions. Its formed structure can not only firmly fix the product and prevent it from moving and being damaged during transportation, but also enhance the display effect of the product through a transparent or translucent appearance design. Especially in markets that need to highlight product features and enhance brand image, the application value of this material is particularly significant.

Excellent Mechanical Strength and Durability

In logistics, transportation, and long-term storage, the mechanical strength and durability of packaging materials are crucial. Conductive PS blister sheet provides comprehensive physical protection for a variety of products with excellent impact resistance and abrasion resistance. This material can effectively absorb and disperse external impact forces, reducing possible damage during transportation. In addition, the wear resistance of the conductive PS blister sheet allows it to withstand multiple handling and operations without losing its original protective properties due to wear and tear. In contrast, traditional plastic or paper packaging materials often have shortcomings in durability and impact resistance, which can easily lead to product damage or packaging failure during transportation, thus increasing costs and risks for companies. By using the conductive PS blister sheet, companies can significantly improve logistics efficiency and reduce returns and customer complaints due to product damage.

Environmental Protection and Sustainability

As the global awareness of environmental protection increases, companies are paying more and more attention to their environmental protection and sustainability when choosing packaging materials. Conductive PS blister sheet not only excels in functionality but also complies with modern environmental standards. This material can be recycled, effectively reducing resource consumption and environmental pollution. In addition, the production process of conductive PS blister sheet is also relatively environmentally friendly, requiring low energy consumption and reducing the carbon footprint. In many countries and regions, governments have increasingly strict environmental requirements for packaging materials. Conductive PS blister sheet helps companies better comply with these regulations and establish a green and environmentally friendly brand image due to its recyclability and low environmental impact. At the same time, its environmental protection characteristics also meet consumer demand for green products, making it more competitive in the market.

Wide Range of Applications

Conductive PS blister sheet is not only an ideal packaging material for electronic products, it is also widely used in many fields such as medical devices, automotive parts, and precision instruments. For example, in medical device packaging, the conductive PS blister sheet can prevent devices from being damaged by static electricity accumulation during storage and transportation, while maintaining the sterility and integrity of the device. In the automotive industry, this material is used to protect various electronic control modules, sensors and other sensitive components from damage on the assembly line or in transit. In addition, the application of a conductive PS blister sheet is also indispensable in many industrial equipment that require highly precise protection. Its versatility and wide applicability make it an indispensable packaging solution in multiple industries.

Related products

-

Quick View

Matte PC Overlay Panel – Custom Print, LED Window & Mounting Holes

Contact UsElectrical panel Matte PC Polychrome printing+Positioning hole+Display window+Convex hull button

-

Quick View

Juice pot, cold water pot, lemon pot, hammered pattern pot, suitable for kettles in homes and restaurants

Contact UsMade of high-quality acrylic material, high transparency, lightweight, and impact resistant. Its production process is exquisite and the surface is smooth. Modern design, beautiful hammer pattern, and ergonomic curved handle. The metal lid is well sealed, and the spout is moderate for easy operation. Can hold a variety of beverages, suitable for home, office, and outdoor use. Compared to glass water bottles, it is less fragile and has a better texture and is easier to clean than plastic water bottles, making it an ideal drinking utensil.

-

Quick View

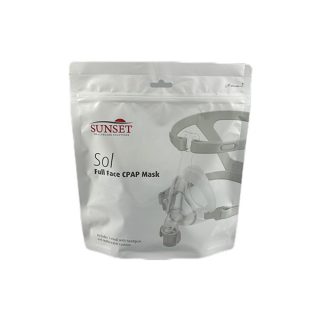

Mask packing bag customization

Contact UsOur mask packing bag is suitable for the packaging of various masks, such as medical masks, N95 masks, KN95 masks, ordinary masks, etc.

-

Quick View

Juice pot, cold water pot, lemon pot, hammered pattern pot, suitable for kettles in homes and restaurants

Contact UsMade of high-quality acrylic material, high transparency, lightweight, and impact resistant. Its production process is exquisite and the surface is smooth. Modern design, beautiful hammer pattern, and ergonomic curved handle. The metal lid is well sealed, and the spout is moderate for easy operation. Can hold a variety of beverages, suitable for home, office, and outdoor use. Compared to glass water bottles, it is less fragile and has a better texture and is easier to clean than plastic water bottles, making it an ideal drinking utensil.

Reviews

There are no reviews yet.