Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

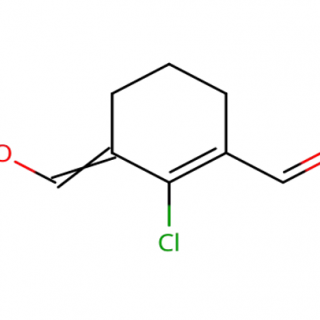

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

Milled carbon fiber for plastic reinforcement

Carbon fiber powder can enhance the mechanical, thermal, and functional properties of plastics by regulating the interface bonding and dispersion state.

Mechanical Reinforcement Mechanism

-

Load Transfer: After uniform dispersion, carbon fiber powder acts as a "rigid skeleton" to bear external loads and reduce the deformation of the plastic matrix. When the addition amount is 10%-20%, the tensile strength of the composite material can be increased by 50%-150%, and the flexural modulus can be increased by 100%-300%.

-

Inhibition of Crack Propagation: The high tear resistance of carbon fiber powder can block the spread of cracks in the plastic matrix and improve the impact resistance (for example, after adding 15% carbon fiber powder to PA6, the notched impact strength is increased by about 30%).

Improvement of Thermal Properties

Enhancement of Functionality

Engineering Plastics: PA (Nylon)

-

Application Scenarios: Automotive gears, bearing cages, high-pressure valve components.

-

Formula Design: Adding 10%-30% carbon fiber powder (particle size 5-15μm, surface amination treatment) can increase the tensile strength of PA6 from 75MPa to over 120MPa, while reducing water absorption (to minimize dimensional changes).

Special Engineering Plastics: PEEK

-

Application Scenarios: Aerospace structural parts, medical implants, high-temperature bearings.

-

Technical Points: The melting temperature of PEEK (343℃) is close to the oxidation temperature of carbon fibers. It is necessary to use carbon fiber powder with an anti-oxidation coating (such as nickel-plated or silicon-plated). When the addition amount is controlled at 15%-25%, the flexural modulus of PEEK can be increased from 3.8GPa to over 8GPa.

General Plastics: PP (Polypropylene)

-

Application Scenarios: Automotive bumpers, electronic device housings (with antistatic requirements).

-

<span style="-weBe the first to review “Milled carbon fiber for plastic reinforcement” Cancel reply

Related products

-

Quick View

Auto Parts

Contact UsGeneral New Material (Wuxi) Co., Ltd. is a comprehensive enterprise specializing in the production of high-performance Sheet Molding Compound (SMC), integrating design, R&D, and customer-centric services into its operations.

-

Quick View

Rubber Anti Vibration Mount Pad For Vehicle Rubber Automotive Shock Buffer Manufacturer From China

Contact UsCompression-molded vibration isolation pads. 75% energy absorption. Operating range: -30°C~110°C.UV-resistant compounds. MOQ 500pcs, 15-day lead time.

-

Quick View

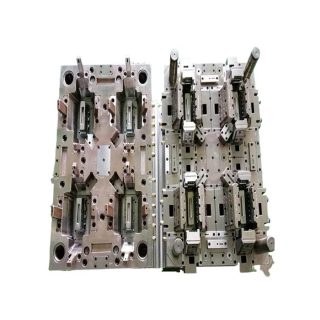

Automotive Interior Molds

Contact UsMold material: S50c, PX5, 738 heat treatment, SKD61 heat treatment

-

Quick View

Chopped glass fiber for friction materials

Contact UsAs an important reinforcing material, chopped glass fiber plays a vital role in friction materials.

Reviews

There are no reviews yet.