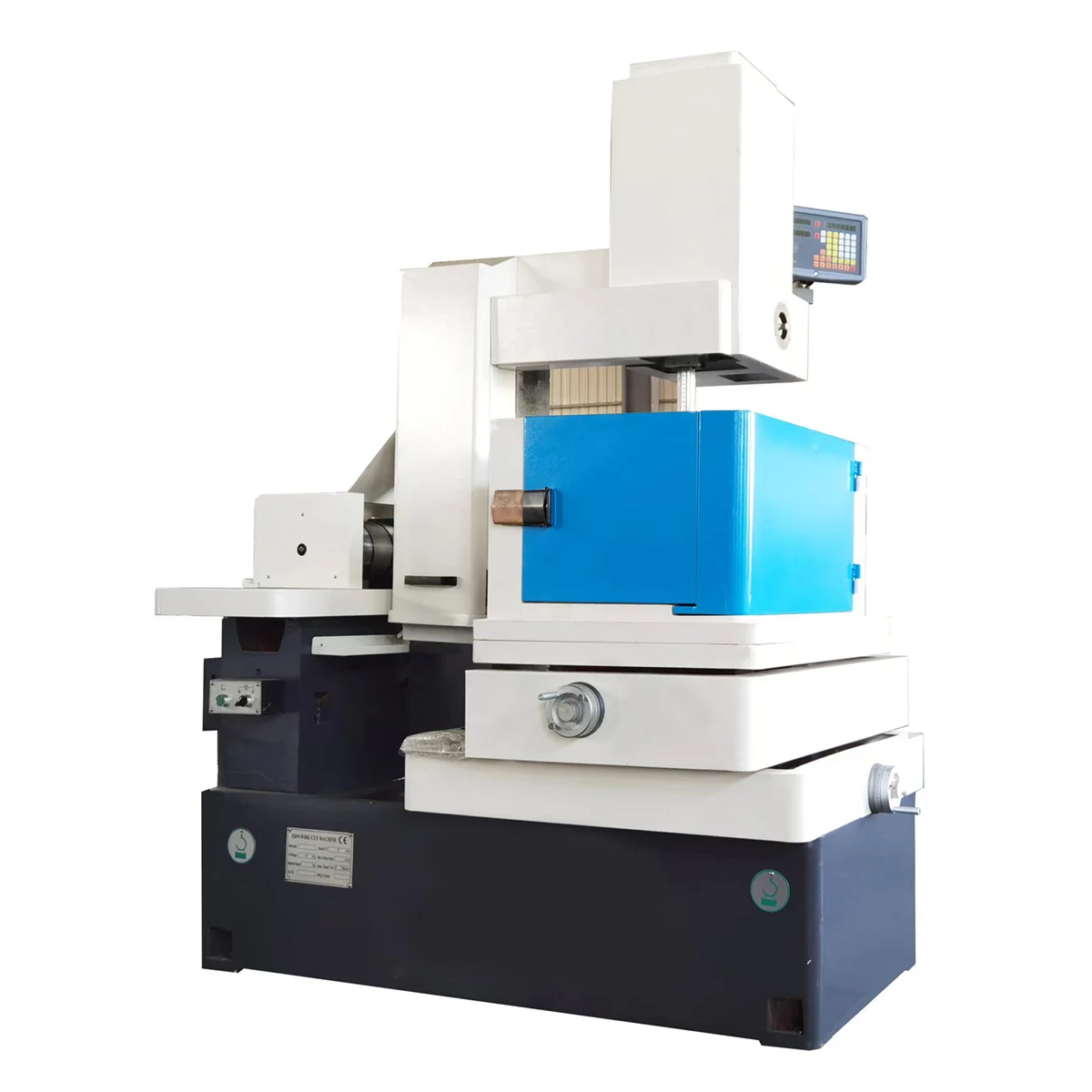

BF350C BF450C Heavy Dudy High Precision Edm Wire Cut Machine

Robust frame with “C” mast.

With height adjustable diamond guider.

Four axes independent (X/Y/U/V) work;

Taiwan linear rail, Grade P or H, Ball screw. C2 or C3.

Special Tensioning mechanism for molybdenum wire, keep stable cutting.

Stepper motor is standard, Servo motor is optional.

Tolerance can keep in 0.005mm, Roughness Ra 0.8.

Multi-cut EDM Wire Cutting Machine (C type)

Robust frame with "C" mast.

With height adjustable diamond guider.

Four axes independent (X/Y/U/V) work;

Taiwan linear rail, Grade P or H, Ball screw. C2 or C3.

Special Tensioning mechanism for molybdenum wire, keep stable cutting.

Stepper motor is standard, Servo motor is optional.

Tolerance can keep in 0.005mm, Roughness Ra 0.8.

Technical Parameters:

| Model | BF320C | BF350C | BF400C | BF450C |

| Working table size (mm) | 500×720 | 550*780 | 580×820 | 650*880 |

| Table travel (X/Y) (mm) | 320×400 | 350×450 | 400×500 | 450×550 |

| Max.cutting thickness (mm) | 400 | 300 | 400 | 300 |

| Max. load on workingtable (KG) | 400 | 500 | 600 | 800 |

| Travel size (U/V) (mm) | 24×24 (±3°) ( optional: 30×30 75×75 135×135) | |||

| Wire Dia. (mm) | (Molydbenum wire) φ0.10~0.22 ( special 0.25, 0.30mm) | |||

| Wire speed (m/sec) | 2.0-11.0 | |||

| Max. cutting speed (mm2/min) | 160-180 | |||

| Max.cutting angle | ±3°/80mm ( ±6° ±15° ±30°degree is optional) | |||

| Process accuracy (mm) |

(Multi-cut): 10×10×30(Square)≤0.008; (One time-cut)≤0.012; (Multi-cut)(Octagon)≤0.01; (Straightness)≤0.008/50mm; |

|||

| Roughness (Ra.um) | Multi-cut):Ra≤0.8, Single-cut):Ra≤2.0 | |||

| Driving motor | Step motor / AC servo motor* (Optional) | |||

| Guide rail and ball | Precision ball screw/Linear rail | |||

| Tension system | three stage(0/1/2)tension adjustable | |||

| Power supply | 380V/50Hz, 2.5kw | |||

| Weight (kg) | 1600 | 1700 | 1800 | 2000 |

| Dimension (mm) | 1700*1400*1900 | 1700*1500*1900 | 1900*1500*1900 | 1900*1550*2000 |

Company & Workshops

BOFENG Machinery is a group with 4 factories. BOFENG has about 60000 square

meter work shop.

Production Equipments

The main parts of our machines are processed by cnc machine. We have gantry

type cnc milling machine, cnc vertical machining center, gantry type cnc

grinding machine, cnc laser cutting machine, cnc bending machine, cnc shearing

machine.

Test & Inspection

All machines will be tested before shipment.

Package & Delivery

Related products

-

Quick View

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

-

Quick View

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

Reviews

There are no reviews yet.