Semi-automatic Hub Bearing Unit Assembly Line

● SMALL FOOTPRINT / QUICK CHANGEOVER / FLEXIBLE OPERATION / DATA TRACEABILITY

● FREE COMBINATION / SIMPLE OPERATION

Product Introduction

Quality Assurance / Long Warranty / Worry-free Operation

-

Product Name: Semi-automatic Hub Bearing Unit Assembly line

-

Advantage: The production line work pace of 15-18 seconds per set(Non-manual participation).

-

Features: Free combination of processes, small footprint and quick changeover.

Some Details

Intelligent / Green Practitioner

|

1: Out Ring Grease Injection Machine Automatical and uniform grease injection High-precision grease injection No residue |

2: NEGATIVE CLEARANCE DETECTION MACHINE AUTOMATIC OPERATION VISUAL DISPLAY HIGH-PRECISION MEASUREMENT |

3: END-HOP DETECTION MACHINE RAPID DETECTION VISUAL DISPLAY STRONG ADAPTABILITY AND VERSATILITY |

|

|

|

CASE SHOW

High Efficiency / High Precision / High Quality

Related products

-

Quick View

FLIP-FLOP TYPE DEPANNER

Contact UsGuangdong Baimai Equipment Technology Company was established in Dongguan, the city is located in China’s global bay area “Guangdong-Hong Kong-Macao Greater Bay Area”, known for its manufacturing.

-

Quick View

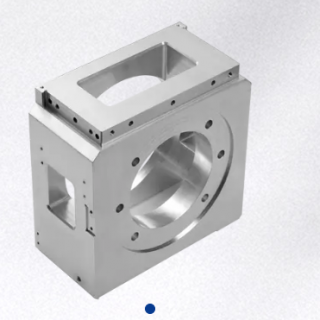

Extruded heatsink

Contact UsSurface Finish:Powder Coating, Anodizing, Brushing, Polishing, Electric-plating,powder Coating, Hot Dip Galvanizing, E-coating, Tin Plating,Nickel Plating, Chrome Plating,Decorate, Enamel Coating etc.

-

Quick View

Automated Thermoforming Machine for Dental Aligner

Contact UsDesigned specifically for clear aligner post-processing, this specialized equipment heats and softens the medical film material before precisely pressing it onto a 3D-printed dental mold

Reviews

There are no reviews yet.