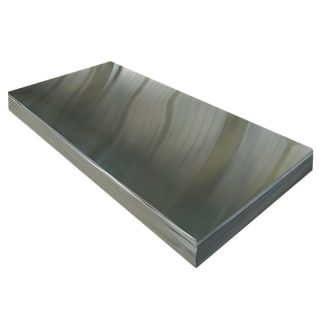

304 Stainless Steel Pipe

304 stainless steel pipe is the most common type of steel pipe across the globe for a number of its characteristics. 304 stainless steel is primarily composed of iron, chromium and nickel. This combination gives rise to outstanding oxidation resistance and corrosion resistance. 304 stainless steel is a versatile stainless steel material with better anti-rust properties than 200 series stainless steel materials. It also outperforms them in high temperature resistance. 304 stainless steel pipe features a smooth surface, high plasticity, toughness and mechanical strength, and is very resistant to corrosion by acids, alkaline gases, solutions and other media. 304 stainless steel pipes are widely used in food processing equipment, building materials, automobile parts and other fields for its versatility and relatively low cost.

Product Description

|

Product Name |

304 Stainless Steel Pipe |

|

|

Type |

Steel Pipe |

|

|

Outer diameter |

Round Tube |

4mm-200mm |

|

Square Tube |

10*10mm-100*100mm |

|

|

Rectangular Tube |

10*20mm-50*100mm |

|

|

Wall Thickness |

0.6mm-6.0mm |

|

|

Length |

1-6 meters, Length can be customized |

|

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

|

Surface |

Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. |

|

|

Scope of Application |

Common applications for stainless steel pipes include food processing, Textile operations, Breweries, Water treatment plants, Oil and gas processing, Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. |

|

|

Certificate |

ISO, SGS, BV, etc. |

|

|

Production Technology |

Hot Rolling, Cold Rolling |

|

|

Edge Processing |

Edging, Trimming |

|

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.08 |

≤1.0 |

≤ 2.0 |

18.0~20.0 |

8.0~10.5 |

≤ 0.03 |

≤ 0.035 |

Mechanical Properties

|

Tensile StrengthKb (MPa) |

Yield Strengthσ0.2 (MPa) |

ElongationD5 (%) |

Hardness |

|

≥ 520 |

≥ 205 |

≥ 40 |

≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

8.03 |

193 |

16.9 |

16.2 |

72 |

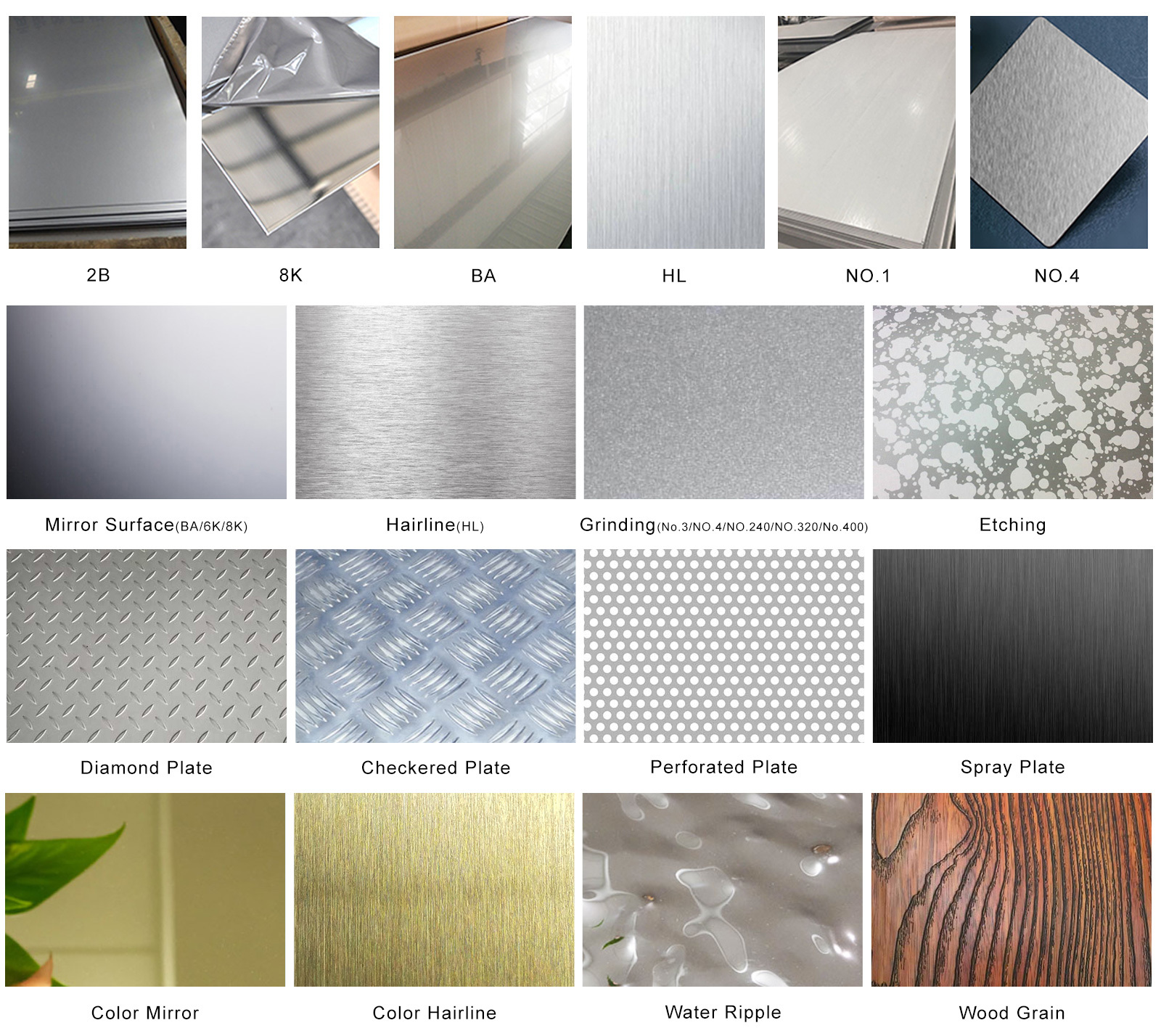

Surface Selection

Related products

-

Quick View

A283/Q195 Cold Rolled Steel Coil

Contact UsA283 steel coil exhibits excellent work hardening properties during cold forming for its high strength and plasticity. After repeated cold working deformation, the coil can still show similar strength and hardness, with even better ductility and toughness. In addition, due to its good welding performance, the coil can be easily welded into parts of various shapes and sizes, and the welding quality is stable and reliable. A283 steel coils are widely used in the manufacturing of various mechanical parts, such as bolts, nuts, pins and other standard parts as well as various non-standard mechanical parts. In addition, they are also used in the manufacture of building structural materials.

-

Quick View

XM-19 Stainless Steel Plate

Contact Us● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month;

● Payment terms L/C, T/T;

● It can pack by container or bulk vessel.

● Standard export seaworthy package, it use steel belt with bundle according product’s size.

● We can make it as your requirement. -

Quick View

409 410 Stainless Steel Plate

Contact Us● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month;

● Payment terms L/C, T/T;

● It can pack by container or bulk vessel.

● Standard export seaworthy package, it use steel belt with bundle according product’s size.

● We can make it as your requirement. -

Quick View

Customized Strong magnet de-ironing separator, N35-N52 grade

Contact UsSize: diameter from 1.5-70mm, length from 0.5-100mm. The magnet grade is at least N35.

Information in need: The magnet and the stainless steel grade, size, surface treatment, magnetizing direction, the quantity. Especially when the magnetic force and the temperature are in specific need.

Reviews

There are no reviews yet.