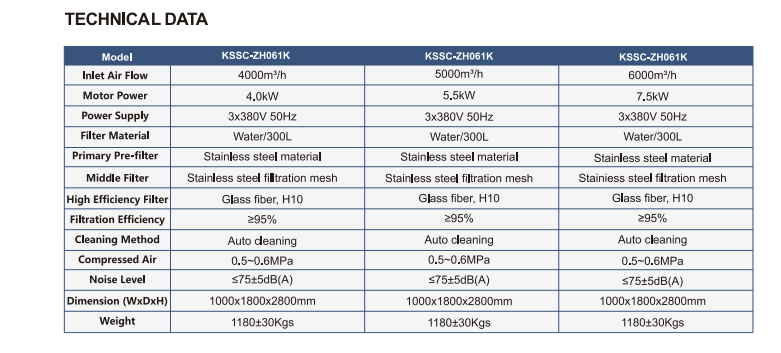

Kssc-zh061k Wet Grinding Dust Collector

It is main applied to flammable, explosive and big spark metal dust.

The air with dust entries into dust collector through suction inlet section under the fan working status, the bigparticles will drop into water tank bottom.

Function:

It is main applied to flammable, explosive and big spark metal dust.

The air with dust entries into dust collector through suction inlet section under the fan working status, the bigparticles will drop into water tank bottom.

The fine particles will pass the water wall is generated by stainless steel vortex coiler, and the fine particles are mixed with water and dropped into water tank bottom.

The V shape aluminum alloy water fender intercepts the fine water mist.

The stainless steel sintering mesh makes gas-liquid separation,PLC controls auto cleaning.

Two pieces glass fiber HEPA filter which purifies the tiny dust particles.

Related products

-

Quick View

PP Rainwater Module 50T(Green)

Contact UsPP plastic modules are injection-molded from polypropylene. By enveloping the structure with a composite geotechnical membrane, the system can function as either a storage reservoir.

-

Quick View

Waste liquid and waste gas incineration device

Contact UsThe furnace volume of the combined incinerator is based on the exhaust gas generated by incineration, the comprehensive residence time is ≥4s, the high-temperature (1100℃) incineration treatment is ≥1100℃, and the high-temperature section residence time is ≥2.5s to ensure the removal efficiency of organic matter.

-

Quick View

Hob

Contact UsIt is used Can-making/Metal sheet Painting and Printing Ovens. According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the wicket, allowing the sheet (aluminum plate) to dry and run in a separate state from the wicket, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

-

Quick View

KSZHDM-03 Combined Grinding Dust Collector

Contact UsGrinding and polishing is an indispensable process in the process of metal processing.

Reviews

There are no reviews yet.