Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Bottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Bottle blowing molds are suitable for various PET appliances in the beverage industry, such as water bottles, carbonated bottles, hot-fill bottles, sterile bottles, etc.

Containers for other industries, such as edible oil, condiments, cosmetics, personal protective equipment, medicine, etc.

Different two-step equipment, such as Sidel, KRONES, KHS, Tech-Long, Newamstar, etc.

Different one-step equipment, such as SIPA, ASB, AOK

Features of Sterile Bottle Blow Mold:

1. High-Quality Material:

The sterile bottle blow mold is made from premium quality materials, ensuring durability and longevity.

2. Sterilization Compatibility:

This sterile bottle blow mold is designed to withstand high-temperature sterilization processes, making it suitable for use in pharmaceutical and medical industries.

3. Precision Engineering:

The sterile bottle blow mold is manufactured with precision engineering techniques, resulting in accurate and consistent bottle shapes and sizes.

4. Easy to Use:

The mold is user-friendly, allowing for easy installation and removal, reducing downtime during production.

5. Customizable Options:

Sterile bottle blow mold offers customizable options, allowing for the production of bottles with various shapes, sizes, and neck finishes to meet specific requirements.

6. Cost-Effective:

The mold's efficient design and high-quality construction contribute to cost savings in the long run.

7. Easy Maintenance:

The sterile bottle blow mold requires minimal maintenance, ensuring smooth and uninterrupted production.

8. Compatibility:

It is compatible with various blow molding machines, providing flexibility and versatility in production processes.

9. Consistent Performance:

The sterile bottle blow mold delivers consistent and reliable performance, ensuring high-quality bottle production every time.

If you are interested in blow mold, please feel free to contact us. Quan Quest will give you reasonable price and awesome services.

Related products

-

Quick View

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs! -

Quick View

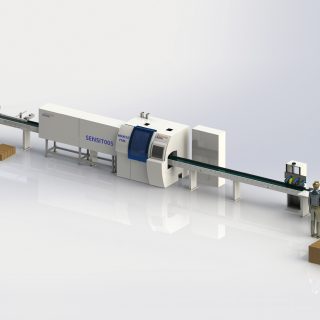

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

Quick View

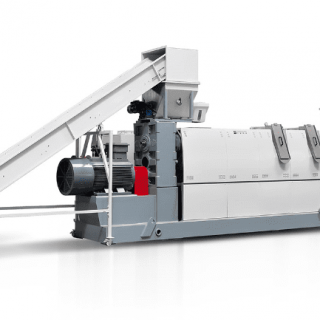

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

Quick View

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

Reviews

There are no reviews yet.