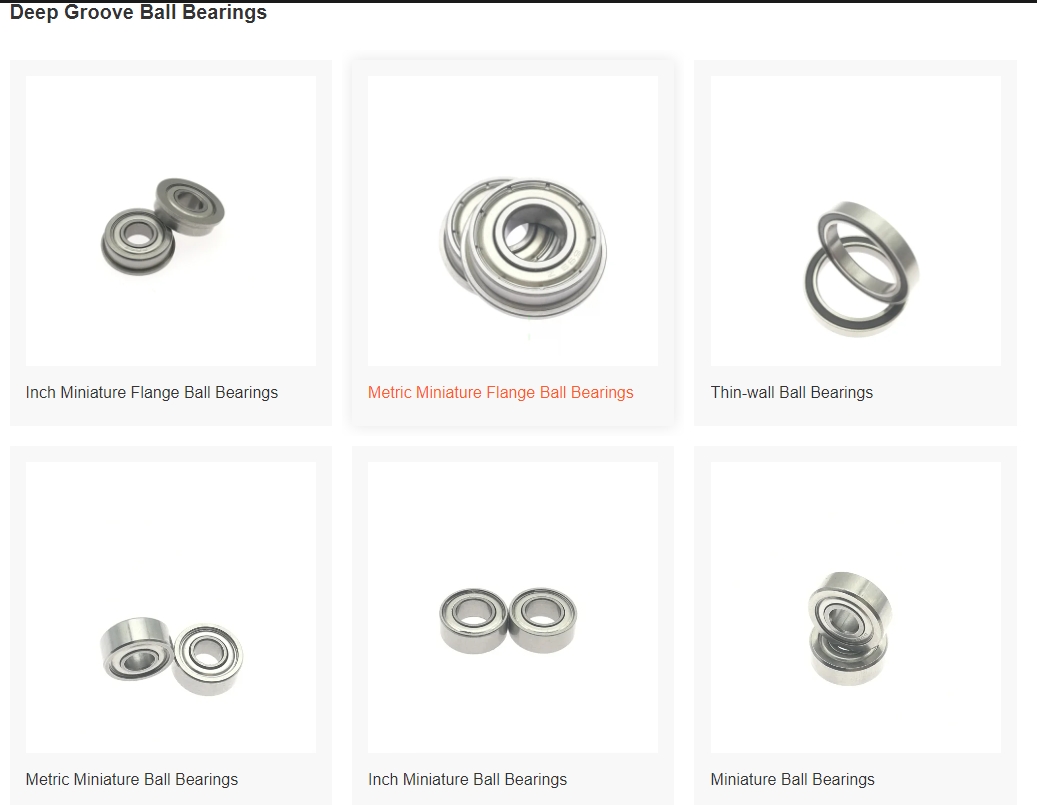

Deep Groove Ball Bearings

Deep groove bearings are a widely used bearing type known for their simple design and excellent performance.

https://www.fertbearing.com/Deep-Groove-Ball-Bearings

Deep groove bearings are a widely used bearing type known for their simple design and excellent performance. Deep groove bearings can withstand radial and axial loads and are suitable for a variety of rotational speeds and temperature conditions. Deep groove bearings are characterized by having one or two side grooves extending deep into the inner ring, which allows the bearing to accommodate more rolling elements, thus improving its load-bearing capacity and rigidity.

Deep groove ball bearings are one of the most common bearing types and are favored for their simple design, ease of maintenance, and wide range of applications. These bearings are mainly composed of inner rings, outer rings, cages and a large number of steel balls, and are suitable for bearing radial and axial loads. The design of the deep groove ball bearing allows stable performance during high-speed rotation while having a low coefficient of friction and good wear resistance.

Applicable fields:

Wuxi F&T Machinery Co., Ltd. is a deep groove ball bearing exporter and deep groove bearing company. Deep groove ball bearings are widely used in a variety of industries and equipment, including but not limited to:

– Automobiles and vehicles

– Motors and power tools

– Agricultural and construction machinery

– Food processing and packaging equipment

– Medical and laboratory equipment

– Home appliances and office automation equipment

Selection Guide:

When choosing a deep groove ball bearing, you need to consider the following factors:

– Load type and size

– Speed requirements

– Working environment and conditions

– Maintenance and lubrication requirements

– Dimensions and installation requirements

Our technical team can provide professional selection advice and technical support to help you find the deep groove ball bearing that best suits your application.

Related products

-

Quick View

Automobile differential gear

Contact UsThe company’s main products are high precision involute cylindrical gears,We specialize in manufacturing of gears products such as spur gear,helical gear, herringbone gear, external spline…

-

Quick View

DIN-EN 856 4SH

Contact UsSTANDARD: EN856 4SH MT98 4SH

COVER: oil resistant neoprene

REINFORCEMENT: four spiral high strength copper-coated steel wire

COVER; friction & weather resistant special rubber

TEMPERATURE RANGE: -40℃ /+100℃ ; -40 °F/+212°F LT-55 & HT150℃ customizable

APPLICATION: suitable for oil and water based fluid hydraulic system, construction machinery, agricultural machinery, oil drilling, mining machinery, iron and steel, chemical industry, energy, rail transit, food processing machinery and shipbuilding -

Quick View

Atlas Copco KIT NON RETURN VALVE 2901107700

Contact UsFind the genuine Atlas Copco KIT NON RETURN VALVE 2901107700 at RUNGO—high-quality, reliable parts for your equipment. Order now for fast delivery!

-

Quick View

Automotive precision parts

Contact UsWuxi Aojin Hydraulic Machinery Co., Ltd. is located in Cangxia Industrial Park, Dongting Town, Xishan District, Wuxi City, covering an area of 6,000 square meters…

Reviews

There are no reviews yet.