Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

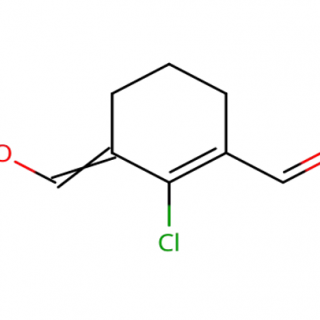

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

Hydraulic tilting Kneader

Mainly used in ink silicone rubber,plastic,pencils,heat-shrinkable material,paints,mosquito coils,carbon graphite,oil,gum base,various viscosity of CMC,modified starch,BMC ,SMC,etc.

https://www.globalkneader.com/Hydraulic-tilting-Kneader.html

Mainly used in ink siliconerubber,plastic,pencils,heat-shrinkable material,paints,mosquito coils,carbon graphite,oil,gum base,various viscosity of CMC,modified starch,BMC ,SMC,composite manhole cover,pharmaceuticals industry etc.Agitator and the part contact with material is made of stainless steel,which could corrosion-resistant and non-rust,also ensure the material chemical properties. Bearing support uses self-aligning bearing with the feature of no movement along shaft.

|

Type |

Volume/L |

Electrical power/kw |

Power/kw |

Steam/Mpa |

Speed/rpm |

|

NHF-5L |

5 |

0.75-1.5 |

0.15 |

0.3 |

N1=59,N2=35 |

|

NHF-40L |

40 |

2.2-5.5 |

3 |

0.3 |

N1=59,N2=35 |

|

NHF-100L |

100 |

4-11 |

4 |

0.3 |

N1=40,N2=21 |

|

NHF-300L |

300 |

11-22 |

8 |

0.3 |

N1=40,N2=21 |

|

NHF-500L |

500 |

15-30 |

16 |

0.3 |

N1=36,N2=21 |

|

NHF-1000L |

1000 |

18.5-55 |

24 |

0.3 |

N1=33,N2=22 |

|

NHF-1500L |

1500 |

22-55 |

36 |

0.3 |

N1=38,N2=21 |

|

NHF-2000L |

2000 |

37-75 |

48 |

0.3 |

N1=25,N2=17 |

|

NHF-3000L |

3000 |

45-90 |

60 |

0.3 |

N1=25,N2=18 |

|

NHF-4000L |

4000 |

55-110 |

66 |

0.3 |

N1=33,N2=20 |

|

NHF-5000L |

5000 |

90-132 |

0.3 |

N1=36,N2=21 |

Related products

-

Quick View

FSH-FMI2020-B Standard Single/Double Channel Fluid Injection

Contact UsFSH – FMI2020 – B standard series of high-precision fluid dispensing / refilling system consists of a digital control box, stepper motor and one to two high precision rotary ceramic pump modules driven by step motor.

-

Quick View

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

Quick View

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Reviews

There are no reviews yet.