Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

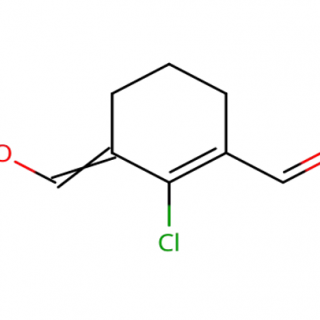

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

JS-04 Low Viscosity Polymer Filtration Reducer

JS-04 is the polymer fluid loss additive of amphoteric and temperature and salt resistance using redox initiator system by AM, AA, AMPS, SA and DMDAAC with water as solvent. DF-03 can reduce the filtration loss, improve the mud cake quality, has good ability of high temperature resistance, salt and calcium contamination resistance. DF-03 has low viscosity to mud system due to narrow molecular weight scale. It is especially suitable for freshwater, saltwater, seawater drilling and completion fluids. The recommend dosage is 3.0 – 7.0ppb.

Product Description

JS-04 is the polymer fluid loss additive of amphoteric and temperature and salt resistance using redox initiator system by AM, AA, AMPS, SA and DMDAAC with water as solvent. DF-03 can reduce the filtration loss, improve the mud cake quality, has good ability of high temperature resistance, salt and calcium contamination resistance. DF-03 has low viscosity to mud system due to narrow molecular weight scale. It is especially suitable for freshwater, saltwater, seawater drilling and completion fluids. The recommend dosage is 3.0 – 7.0ppb.

Technical Specification DBW JS-04

|

Items |

Specifications |

|

|

Appearance |

White or light yellow powder |

|

|

Moisture,% |

≤12.0 |

|

|

Apparent Viscosity (1% water solution), mPa·s |

≤5.0 |

|

|

Effective content, % |

≥70.0 |

|

|

FLAPI after 150℃/16h Aging, mL |

Freshwater Mud |

≤15.0 |

|

Composite saltwater mud |

≤15.0 |

|

Features

Low viscosity effect, can be used for high density drilling fluid due to slight impact to rheology.

Reduce filtration effectively with low dosage.

Improve mud cake quality and inhibit clay dispersing.

Perform well up to 170 ℃, can be used in deep wells.

Resist salt to saturation and resist calcium and magnesium well. It can be applied in freshwater, saltwater, saturated saltwater and seawater drilling and completion fluids.

Pilot test is recommended before its used in KCl and Polyamine and other strong inhibition drilling fluids.

Package and Storage

They shall be packaged in 25kg multi-wall paper sacks. They shall be stored in a shady, dry, and ventilated place.

Safety

They shall be avoided contact with eyes, skins and clothes, otherwise flush it with water. Handling methods and dangerous data shall be referred to MSDS.

Related products

-

Quick View

KSZHDM-03 Combined Grinding Dust Collector

Contact UsFeatures:

● Reasonable structure design facilitates dust settlement

● Convenient dust removal, automatic dust removal to ensure the continuity and efficiency of production

● Low noise and easy to use

● PLC control system control, humanized operation panel design, easy to use

● High filtration accuracy, high efficiency and long service life -

Quick View

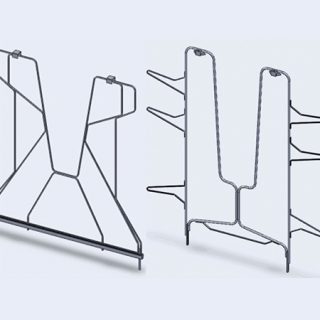

Hob

Contact UsIt is used Can-making/Metal sheet Painting and Printing Ovens. According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the wicket, allowing the sheet (aluminum plate) to dry and run in a separate state from the wicket, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

-

Quick View

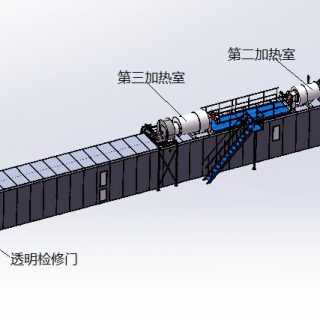

Metal sheet drying oven for can making

Contact UsThe oven is mainly used to dry the coating on the tin (or aluminum) sheet in the can making process. The entire line mainly consists of conveying, feeding devices, drying, cooling, and material collection and stacking.

-

Quick View

KSDC-8604A/A1 Centralized Dust Collector

Contact UsFeatures:

● Compact and reasonable structure design

● Convenient dust removal, fully automatic dust removal, to ensure the continuity and efficiency of production

● Dust collection, container loading and unloading is convenient, the connection with the filter funnel is sealed, no dust leakage

● Intelligent control, optional automatic inverter, remote linkage function

● PLC control system control, humanized design of operation panel, easy to use

● The imported high-quality polyester filter material is used, and the surface of the filter material is covered with a high-precision PTFE membrane, which has higher filtration accuracy and higher filtration efficiency

Reviews

There are no reviews yet.