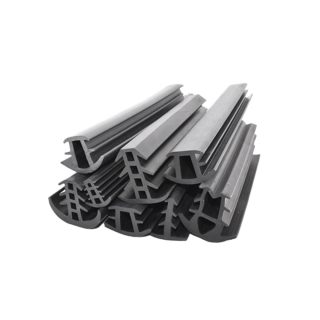

Rubber Tube

After 30 years, five locations, and three generations of hard work, ZLR successfully maintained the core values established in 1993 with a full commitment to employees, customers, and the community.

With just three machines and 100 square meters of space, Haining Zhengli

Rubber & Plastic Factory began manufacturing custom rubber parts on January

1st, 1993. Founder Yuezhong Wang and his family built the company from the

ground up on a foundation of commitment, hard work, quality service &

products, and family values which are "To Be Honest, To Do Best".

Shortly after its establishment, during a period of growth, ZLR encountered a

significant challenge as the founder's father was diagnosed with cancer. Mr.

Wang utilized all of his resources to treat his father but unfortunately, he

couldn't save him. Mr. Wang continued to pursue excellence, following his

father’s legacy, despite the painful experience. In the ensuing decades, ZLR

continued to grow and expanded further in Haining, Zhejiang in 2008, with the

construction of a 1,500-square-meter facility.

Key milestones include establishing a materials department in 1999, beginning

online sales in 2003, obtaining ISO 9001 certification in 2012, and starting

plastic production in 2016.

To provide much-needed support for this rapidly growing enterprise, Yuezhong

Wang’s son, Andong Wang, joined the factory to support its growth in marketing

after completing his studies in Massachusetts in 2016. The factory adapts to

changing market conditions, seeks new opportunities and is committed to

providing high-quality rubber products and services.

After 30 years, five locations, and three generations of hard work, ZLR

successfully maintained the core values established in 1993 with a full

commitment to employees, customers, and the community.

Features of Rubber Tubes by Zhengli

Zhengli's Rubber Tubes are designed with a focus on durability, flexibility, and resistance to various environmental factors. These tubes are crafted from high-quality materials, ensuring they can withstand the test of time and provide reliable performance in a variety of applications.

– Durability: Our rubber tubes are built to last, with a strong resistance to wear and tear, ensuring they maintain their integrity even under continuous use.

– Flexibility: The flexibility of Zhengli's rubber tubes allows them to be easily maneuvered and installed in tight spaces, making them a versatile choice for various setups.

– Chemical Resistance: These tubes are formulated to resist a range of chemicals, making them suitable for use in chemical handling and processing industries.

– Temperature Tolerance: Engineered to perform in a wide range of temperatures, Zhengli's rubber tubes can operate effectively from cold to hot environments without losing their structural integrity.

Applications of Rubber Tubes

Rubber tubes from Zhengli are utilized across a broad spectrum of industries due to their adaptability and robust construction. Here are some of the key areas where our rubber tubes excel:

– Industrial Processing: Used in the transportation of fluids and gases in industrial settings, ensuring safe and efficient material handling.

– Automotive: Essential in automotive applications for brake lines and fuel systems, where reliability and safety are paramount.

– Medical Equipment: Our tubes meet stringent quality standards, making them suitable for use in medical equipment that requires high levels of cleanliness and precision.

– Agricultural Irrigation: Durable and flexible enough for use in agricultural settings, where they are used for efficient water and nutrient delivery.

Manufacturing Process of Zhengli Rubber Tubes

At Zhengli, we take pride in our manufacturing process, which is designed to produce high-quality rubber tubes that meet the exacting standards of our customers. Here's an overview of how we create our rubber tubes:

– Material Selection: We carefully select the finest raw materials to ensure the tubes have the necessary properties for their intended applications.

– Compounding: The rubber is compounded with additives to enhance its properties, such as resistance to chemicals, heat, and abrasion.

– Molding: Using advanced molding techniques, we shape the rubber into tubes with precise dimensions and uniform wall thickness.

– Curing: The tubes are then cured under controlled conditions to achieve the desired level of hardness and durability.

– Quality Control: Each tube undergoes rigorous testing to ensure it meets our high-quality standards before it is released for sale.

Zhengli's commitment to excellence is evident in every step of our manufacturing process, ensuring that the rubber tubes we produce are of the highest quality and ready to perform in even the most demanding conditions.

Related news of Rubber Tube

Related products

-

Quick View

PE Double-Wall Corrugated Pipe

Contact UsHDPE Double-Wall Corrugated Pipe is a lightweight, high-pressure resistant solution for sewage and drainage systems. Crafted from high-density polyethylene, it boasts a smooth inner wall and corrugated outer wall, ensuring durability and longevity. With its convenient and reliable connection, this innovative pipe replaces traditional concrete and cast iron alternatives. Ideal for various applications worldwide, it offers fast construction and cost savings, making it the preferred choice for modern infrastructure projects .

-

Quick View

Oil-Resistant Rubber Gaskets – CNC Laser Cut Seals

Contact UsPrecision-cut sealing solutions for engines, pumps and pipelines. Withstands 500PSI pressure & 300°F. UL/FDA/ROHS certified. Samples ship in 48hrs.

-

Quick View

Automotive Door Seals – EPDM Weatherstrip for Cars/SUVs

Contact UsDurable 3-layer EPDM rubber seals with UV protection. Reduces 12dB cabin noise, prevents water leaks, and fits 2005-2023 models. Easy peel-and-stick installation. OEM-certified.

-

Quick View

Rubber Pad for Motor Mounts Rubber Shock Absorber anti-vibration | Vibration Transmission Rate <15%

Contact UsRubber Pad for Motor Mounts Rubber Shock Absorber anti-vibration | Vibration Transmission Rate <15%

Reviews

There are no reviews yet.