Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

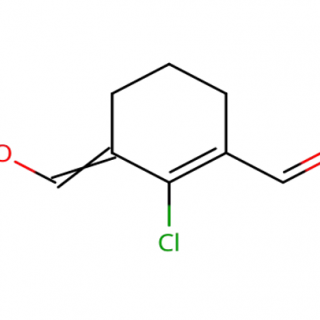

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

Overview

Unique spray process, stable welding selection effect, small batch production of preferred welding equipment, low cost, high flexibility

Product features

Special designed point flux injection;

High precision, high stability selection spot welding (single and double head optional)

Nozzle automatic cleaning , automatic calibration of jet height, automatic addition of solder and miniaturization design;

Configure the AIVS manufacturing platform;

Realize the online repair function by connecting AOI

|

Type |

Specification |

Selective wave soldering machine |

|

Technical parameter |

Machine size |

L800*W1400*H1400mm |

|

Mechanical pump groove |

Standard:single cylinder×1个 |

|

|

Spray nozzle diameter |

φ3-12mm |

|

|

Wave height |

Max:5mm |

|

|

PCB gap |

Min:3mm |

|

|

Tin furnace capacity |

8KG/ Solder furnace |

|

|

Soldering temperature |

Max : 320℃ |

|

|

Temperature control accuracy |

±1℃ |

|

|

Heating time |

40Min/(300℃) |

|

|

Tin furnace power |

1KW/ Solder furnace |

|

|

Moving speed |

X/Y:2 – 400 mm/s |

|

|

Z:2 – 50 mm/s |

||

|

Wave accuracy |

±0.5mm |

|

|

Repeated accuracy |

±0.05mm |

|

|

Spray width |

2-8 mm |

|

|

Size of spray nozzle |

130um |

|

|

Spray way |

Linear |

|

|

Pressure |

0.5Mpa |

|

|

Nitrogen consumption |

1.5m |

|

|

Particles cleanliness |

≥99.99% |

|

|

Nitrogen preheating temperature |

MAX:350℃ |

|

|

Temperature control accuracy |

±1℃ |

|

|

Process visualization |

CCD visible |

|

|

Data import |

Measure Gerber、Images imported online |

|

|

Power |

3P5W,380VAC |

|

|

Frequency |

50/60Hz |

|

|

Consumption |

4.5KW |

|

|

Air supply |

0.5Mpa |

|

|

Automatic solder adding device |

Option |

|

|

Nozzle automatic cleaning device |

Option |

|

|

Spray height correction |

Option |

|

|

AIVS Intelligent manufacturing platform |

Option |

Related products

-

Quick View

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

Quick View

FS-V-F240 Injection valve

Contact UsFS-V-F240 series drip-proof valve is suitable for direct injection of lithium battery which can efficiently avoid liquid dropping and hanging.

-

Quick View

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

-

Quick View

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

Reviews

There are no reviews yet.