Small vacuum plasma device(PR60L , PR80L)

High precision, fast response, good handling and compatibility, perfect functions and professional technical support.

Small vacuum plasma device(PR60L , PR80L)

|

Number |

Project |

Technical Parameter |

|

1 |

Specifications of the whole machine |

PR60L:920mm(W) × 960mm(D) × 1720mm(H) PR80L:920mm(W) ×1030mm(D)×1720mm(H) |

|

2 |

Vacuum chamber specifications |

PR60L: Imported aluminum400(W) ×400(H)×400(D)mm PR80L: Imported aluminum450(W) ×400(H)×450(D)mm |

|

3 |

Electrode plate specifications |

PR60L:6 layer flat plate electrode plate (380(W)×310(D)mm) PR80L:8 layer flat plate electrode plate (420(W)×360(D)mm) |

|

4 |

Control system |

Touch screen + PLC control |

|

5 |

Vacuum measurement system |

Pirani resistance vacuum gauge |

|

6 |

Gas metering system |

Precision mass flow control meterMFC |

|

7 |

Number of gas pathways |

2 channels intake, 1 way venting |

|

8 |

Plasma generator |

500W&1KWPlasma generation source,40KHz (selectable13.56MHz) |

|

9 |

Working gases |

2 working gases are optional:Ar2、N2、H2、O2 |

|

Features |

High precision, fast response, good handling and compatibility, perfect functions and professional technical support. |

|

|

Industry |

It is suitable for cameras and industries, mobile phone manufacturing, semiconductor IC fields, silica gel, plastics, polymer fields, automotive electronics industry, aviation industry, etc. |

|

|

Application |

1. Camera and fingerprint recognition industry: Oxidation removal on the surface of the gold PAD of the soft hard bonding board; IR surface cleaning and cleansing; 2. In the field of semiconductor ICs, COB, COG, COF, ACF processes are used for cleaning before wire bonding and soldering; 3. Silicone, plastic, and polymer fields: Surface roughening, etching, and activation of silicone, plastic, and polymer. |

|

Related products

-

Quick View

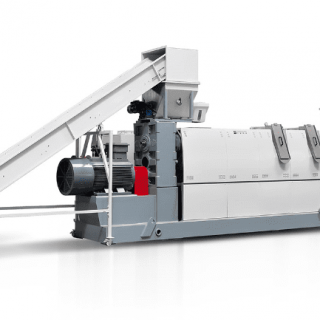

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

Quick View

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

-

Quick View

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs! -

Quick View

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

Reviews

There are no reviews yet.