Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

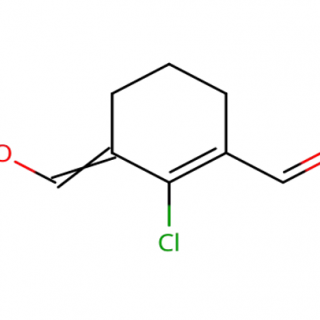

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

Solid-liquid incinerator project for Ningxia

This project is a 10,000 tons/year hazardous waste incineration device for Ningxia, which is used for incineration and treatment of hazardous waste produced by our factory.

Automatic feeding system — automatic feeding system — Rotary kiln — liquid waste furnace — secondary combustion chamber — SNCR denitration system — Waste heat steam boiler — rapid cooling deacidification tower — dry spray tower (lime, activated carbon jet) — cloth bag dust collector — Induced draft fan — SCR denitration system — spray tower — packing spray tower — wet electric dust collector — smoke fontanel — discharge

Related products

-

Quick View

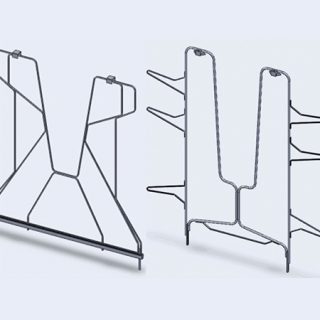

Hob

Contact UsIt is used Can-making/Metal sheet Painting and Printing Ovens. According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the wicket, allowing the sheet (aluminum plate) to dry and run in a separate state from the wicket, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

-

Quick View

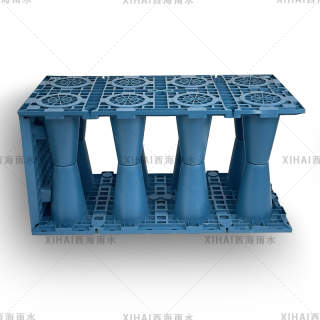

PP Rainwater Module Heavy-duty 60T(Blue)

Contact UsXihai Since 2013, it has been dedicated to the rainwater industry.It is a leading professional service provider for sponge cities in China.

-

Quick View

PP Rainwater Module 50T(Green)

Contact UsPP plastic modules are injection-molded from polypropylene. By enveloping the structure with a composite geotechnical membrane, the system can function as either a storage reservoir.

-

Quick View

PP Rainwater Module 35T(Black)

Contact UsPP plastic modules are injection-molded from polypropylene. They can be interconnected to form an underground water storage tank.

Reviews

There are no reviews yet.