Category

Popular

-

Four-column shelves

Four-column shelves

-

The Ultimate Guide to Choosing the Best Pink Rose Flower Bubble Machine Toy for Your Child’s Safety and Fun

The Ultimate Guide to Choosing the Best Pink Rose Flower Bubble Machine Toy for Your Child’s Safety and Fun

-

DOPRO Engine Storage Racks – Maximize Space, Protect Engines

DOPRO Engine Storage Racks – Maximize Space, Protect Engines

-

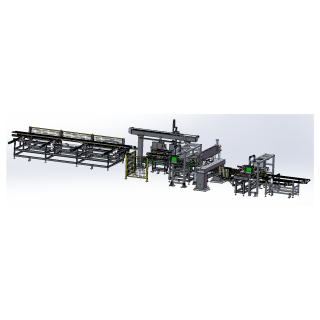

CLW-7000 automatic stamping production line of photovoltaic frame

CLW-7000 automatic stamping production line of photovoltaic frame

-

Full-Print Large Sublimation Summer Vibes Beach Tote Bag

Full-Print Large Sublimation Summer Vibes Beach Tote Bag

Spring Wire Drawing Machine

55CrMnA , 60Si2MnA, 55SiCrA, SAE 9254, 60#,62B,70#,72b,80#,82b, and son on

Used for Spring wire, Automotive springs, compression springs, tension springs, mechanical springs

Spring wire drawing machine

55CrMnA , 60Si2MnA, 55SiCrA, SAE 9254, 60#,62B,70#,72b,80#,82b, and son on

Used for Spring wire, Automotive springs, compression springs, tension springs, mechanical springs

Product line layout :

Pay off device → mechanical peeling remove oxide skin → Sand belt polishing→ Wire drawing machine→ tension adjustment device → Coil type or bobbin type take up machine

φ12mm→φ8mm, φ10mm→φ5mm, φ8mm→φ3mm, φ5.5mm→φ2.5mm,

Max working speed product 300~600m/min

High configuration: Japan control system, Siemens motor, Germany sensor,

Taiwan cylinder, All the same time, We have various types wire drawing

machine for different need, high quality more than good price,Meanwhile

investment cooperation in making galvanized wire machine, Annealing

furnace, nail making machine; include that electrical galvanized and

hot-dip machine, electrical power type and natural type power Annealing

furnace, high speed nail making machine

Parameter

| NO | Capstan Dia(mm) | 700 | 800 | 1000 | 1100 | 1200 |

| 1 | Max.Iniet wire dia | 5.5~6.5 mm | 6.5~8.0 mm | 8.0~10mm | 10~12mm | 12~14mm |

| 2 | Min.Outlet wire dia | 1.5mm | 2.5mm | 3.5mm | 5.5mm | 6.0mm |

| 3 | Drawing passes | 5~10 | 5~10 | 5~10 | 5~10 | 5~10 |

| 4 | Max speed | 300~600 m/min | ||||

| 5 | Main motor power | 22-55 KW | 37 -75KW | 45-75KW | 45-75KW | 75-132KW |

| 6 | Max total wire reduction (%) | 94% | 94% | 94% | 94% | 94% |

| 7 | Wire inlet strength | ≤ 1250 | ≤ 1250 | ≤ 1250 | ≤ 1250 | ≤ 1250 |

| 8 | Take-up Type | Block or Colier | ||||

Show production machine: Inverted type take-up machine, phosphated spring wire, high carbon wire.

Automotive springs, mechanical springs, compression springs, tension springs.

Drawing process in saponification solution results in excellent cooling effect, ensuring the linearity and stable ring size of the spring

These spring wire take-up on blocks ,finished wire weight 100~200kg.

Show Drawing process in saponification solution

Related products

-

Quick View

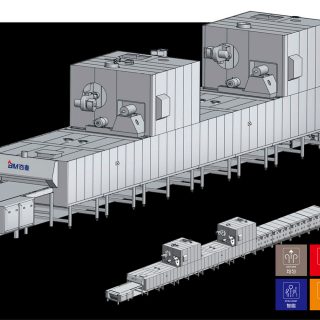

FLIP-FLOP TYPE DEPANNER

Contact UsGuangdong Baimai Equipment Technology Company was established in Dongguan, the city is located in China’s global bay area “Guangdong-Hong Kong-Macao Greater Bay Area”, known for its manufacturing.

-

Quick View

Rail bracket

Contact UsThe elevator guide rail frame is used for supporting and fixing the guide rail, and is installed on the wall of the well or cross beam.

-

Quick View

Premium Automotive Injection Mould – Advanced Technology for Auto Component Production

Contact UsPlace of Origin:Shenzhen,China

Model Number:OEM/ODM

Product:Plastic Injection Mould

Application:Automotive Equipment

Mould material:H13/P20/NAK80/S136/2738/2316/S7/1.2344

Mould Life:250000-300000shots

Surface treatment:Polishing

Certification:ISO9001 ISO13485 IATF16949

Reviews

There are no reviews yet.