Category

Popular

-

Four-column shelves

Four-column shelves

-

The Ultimate Guide to Choosing the Best Pink Rose Flower Bubble Machine Toy for Your Child’s Safety and Fun

The Ultimate Guide to Choosing the Best Pink Rose Flower Bubble Machine Toy for Your Child’s Safety and Fun

-

DOPRO Engine Storage Racks – Maximize Space, Protect Engines

DOPRO Engine Storage Racks – Maximize Space, Protect Engines

-

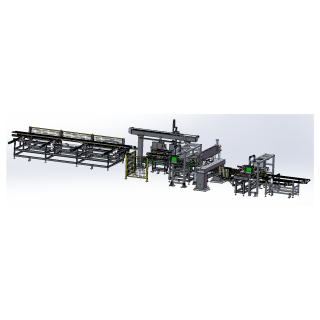

CLW-7000 automatic stamping production line of photovoltaic frame

CLW-7000 automatic stamping production line of photovoltaic frame

-

Full-Print Large Sublimation Summer Vibes Beach Tote Bag

Full-Print Large Sublimation Summer Vibes Beach Tote Bag

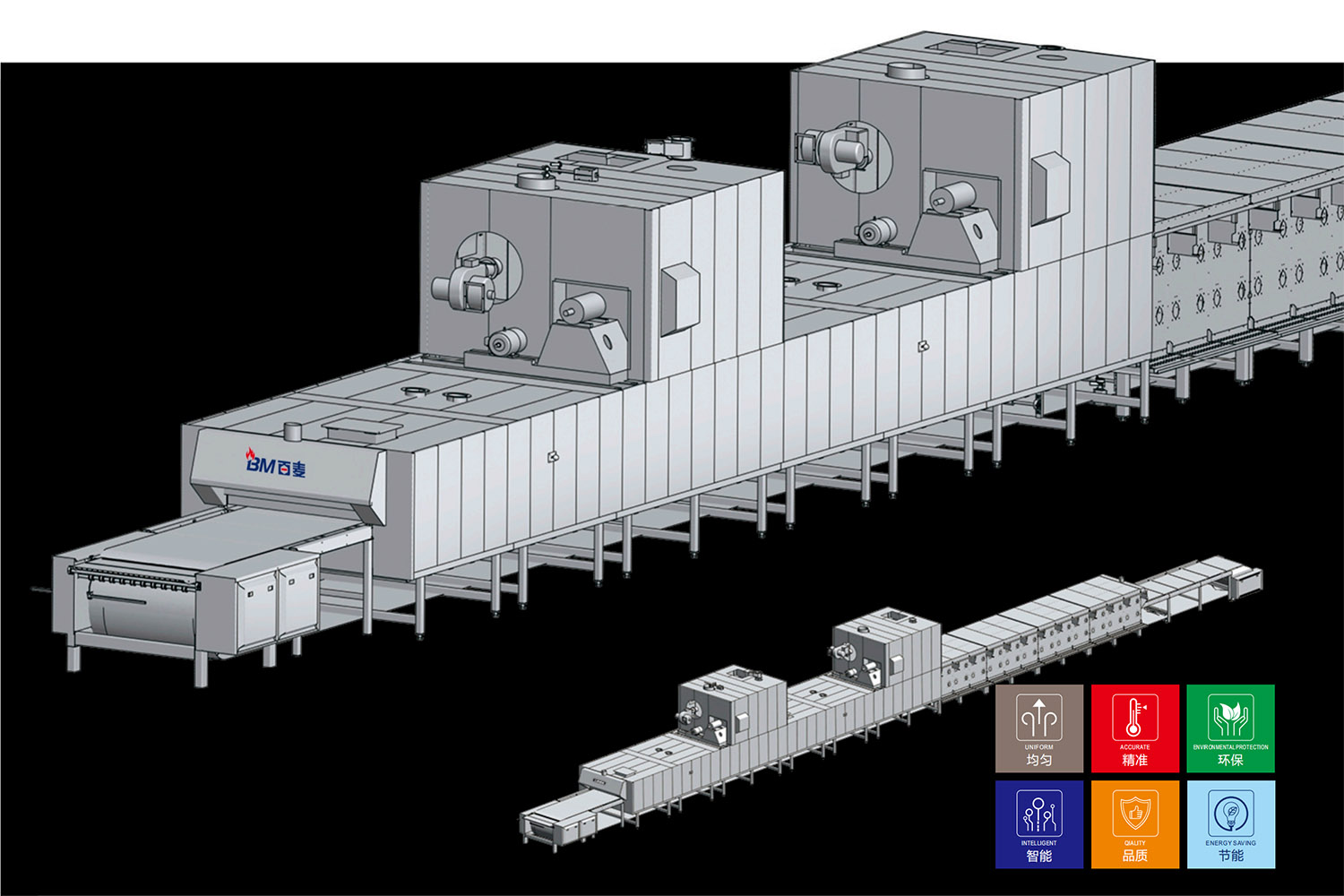

Equipment Function

♦ The hot air produced by combustion is not in contact with the product, and the heat generated by combustion is transferred to the radiant steel plate through the specific channel, which is forced by convection circulation system under the control of the fan, and then to the product through radiation heat transfer.

♦ Full premixed combustion heating, zero pressure proportional temperature control, small thermal inertia, accurate temperature control. Fully burning without gas residue left, high heat utilization rate, energy saving and environmental protection.

♦ Forced hot air circulation device, to ensure that the product is heated evenly with bright color.

♦ Flexible and controllable exhaust system ensures less heat loss under the appropriate moisture requirements, and the energy saving effect is obvious.

♦ Most of the combustion heat is circulated in the channel with very little emission, which ensures the energy saving and environmental protection.

Specification

| SPECIFICATIONS | INNER WIDTH | PASSING HIGHT | EXTERIOR WIDTH | RATED THERMAL POWER | NORMAL HEAT CONSUMPTION |

| Tray size: W600 × H400mm | mm | mm | mm | kcal/m | kcal/m |

| Two trays | 1400 | 220 | 2250 | 12000 | 6000 |

| Three trays | 2100 | 220 | 2950 | 17200 | 8600 |

| Four trays | 2700 | 220 | 3550 | 22400 | 12000 |

Product Category

Related products

-

Quick View

Double plus chains

Contact UsDouble Plus Chains are a specific type of chain link structure that enhances the strength and durability of standard chains. They are often used in various applications, including construction, machinery, and heavy-duty securing. The ‘double plus’ designation indicates an additional layer of interlocking links, providing greater resistance to wear and tear.

-

Quick View

Semi-automatic Hub Bearing Unit Assembly Line

Contact Us● SMALL FOOTPRINT / QUICK CHANGEOVER / FLEXIBLE OPERATION / DATA TRACEABILITY

● FREE COMBINATION / SIMPLE OPERATION -

Quick View

Rail bracket

Contact UsThe elevator guide rail frame is used for supporting and fixing the guide rail, and is installed on the wall of the well or cross beam.

Reviews

There are no reviews yet.