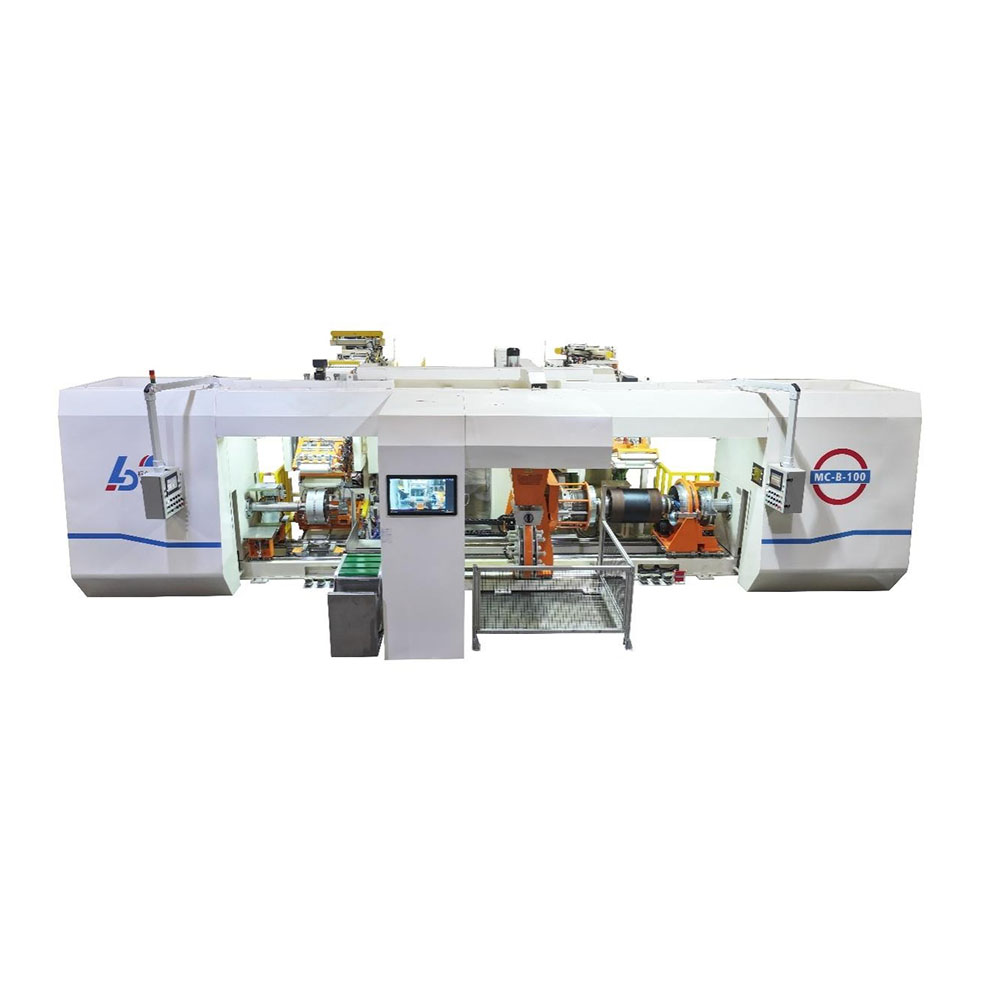

Automatic Bias One Stage Tire Building Machine

● One-step production process ● Integral welded mainframe ● Ball-wrapped carcass drum (with vacuum suction port, suitable for tires without liner)

Product Features:

High efficiency

-

One-step production process

-

Large roll spool

-

Management of matching methods (≥200), one-click switching of specifications

High quality

-

Integral welded mainframe

-

Ball-wrapped carcass drum (with vacuum suction port, suitable for tires without liner)

-

2-stage servo conveyor feeding to improve fixed length accuracy

-

Automatic fixed length and automatic cutting of each layer of material

-

Carcass joint detection (flash seam, wrong angle, big and small head, missing paste)

-

Ultrasonic cutter is used for tread, and the incision of material head and tail is heated

High degree of automation and low labor intensity

-

Movable inner support wire placement seat

-

Automatic drum loading of steel wire ring

-

Automatic drum loading of carcass

-

Automatic tire unloading

-

Management of matching methods, one-click switching of specifications

High safety factor

-

Active safety rope, various photoelectric switch configurations

-

Anti-scalding and anti-pinch design

-

Safety light curtain is configured on the operation side

-

Fault alarm prompt

Wide range of application

-

Applicable to the manufacture of motorcycle tires, agricultural tires and industrial special tires

Equipment Parameters:

|

Lining |

2 layers of fabric |

Buffer layer |

Tread |

|

|

Width range |

80-320mm |

260-450mm |

80-320mm |

215-340mm |

|

Material thickness |

0.4-1.4mm |

0.75-1.2mm |

0.75-1.2mm |

5-14mm |

|

Angle |

90° |

30~54° |

30~54° |

90° |

|

Width of heald cloth |

45mm-50mm |

|||

|

Cutting method |

Disc knife |

Hot hook knife |

Hot hook knife |

Ultrasonic knife |

|

Fixed length method |

Servo fixed length |

Servo fixed length |

Servo fixed length |

Servo fixed length |

|

Secondary fixed length |

Secondary fixed length |

|||

|

Feeding form |

Car |

Car |

Car |

Spool |

|

Drum diameter range |

Drum expansion: 1445±5mm |

|||

|

Drum width range |

200-300mm |

|||

|

Overall dimensions |

12600mm long × 9600mm wide × 3600 mm high |

|||

Equipment Accuracy:

|

Items |

Accuracy |

|

Host rail levelness |

≤± 0.06mm/1000mm |

|

Carcass drum main shaft radial runout |

≤ 0.05mm |

|

Carcass drum main shaft axial runout |

≤ 0.03mm |

|

Tread drum main shaft radial runout |

≤ 0.12mm |

|

Tread drum main shaft axial runout |

≤ 0.03mm |

|

Carrying ring and tread drum coaxiality |

≤ 0.5mm |

|

Carrying ring and carcass drum coaxiality |

≤ 0.5mm |

|

Carrying ring repeat positioning accuracy |

≤ ±0.3mm |

|

Inner rubber fixed length accuracy |

±2mm |

|

Inner rubber laminating accuracy |

±2mm |

|

Cord fixed length accuracy |

±2mm (Two yarns) |

|

Cord single-side joint misalignment |

±2mm |

|

Tread fixed length accuracy |

±2mm |

|

Tread single-side joint deviation |

≤3mm |

Related products

-

Quick View

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

Quick View

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

Quick View

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

Reviews

There are no reviews yet.