Cement silo

Steel silos offer large storage capacity, a short construction period, and low investment costs.Steel silos have a large storage area and excellent homogenization.

Cement Silo Features

1. Structural Safety

Silo structural modeling and calculation ensure silo safety

2. High-Quality Storage

Silo seals ensure a long storage period

3. Worry-Free Discharge

Gasification discharge ensures a high discharge rate

4. Outstanding Quality

Steel sourced from Fortune 500 suppliers ensures quality

Cement production has peak and off-peak seasons, and cement manufacturers need to store cement to balance supply and demand during these periods. Steel silos offer excellent sealing, extending cement storage time and ensuring high cement quality. Cement silos, also known as cement silos, cement containers, or cement storage tanks, are widely used to store cement in cement production plants. AGICO's spiral silos are technologically advanced and offer outstanding performance, unique manufacturing methods, specialized equipment, and mechanized operation. AGICO cement silos are renowned for their robust construction and durability. Cement silos are on-site storage vessels used to store and distribute various types of cement mixtures. Spiral steel silos for storing cement are an integral part of the cement production industry. These silos come in a variety of capacities and sizes, making them an ideal storage solution for many cement silos. AGICO Steel Silos specializes in the production of high-quality spiral cement silos, offering expert services from design and manufacturing to installation of accessories tailored to customer requirements. Long Service Life: The spiral undercut is five times thicker than the original steel plate, significantly enhancing loading resistance and extending the silo's service life. The galvanized steel plate is corrosion-resistant, ensuring the silo's longevity even in adverse weather conditions. Furthermore, the cement silo's durability may reduce maintenance costs.

Short Construction Time: Our steel silo stitching machine can form the silo at 3-5 meters per minute. A 1,000-ton cement silo can be constructed in 5-7 days.

Low Investment: Compared to concrete silos, spiral cement silos require fewer personnel and are easier to transport and install. The short installation period and reduced labor cost can result in significant cost savings.

Moisture Resistance: Our silos are constructed using specialized bending equipment, resulting in tight bends. The cement inside the silo is not affected by external environmental factors such as wind or rain. Excellent air permeability prevents the cement from absorbing moisture from the air.

Galvanized Cement Steel Silo: The galvanized steel silo has a The surface must be smooth, and cement should not cling to the silo's inner walls.

How a Cement Silo Works

Before constructing a cement silo, the silo's base must be erected by a dedicated crane and placed on a precast concrete foundation. The verticality of the erected silo must be checked, and the silo's base must be securely welded to the precast foundation.

After the silo is constructed, if the cement truck's delivery pipe is connected to the silo's feed pipe, cement can be delivered to the silo using air pressure from the bulk cement truck.

During transportation, the operator must press the button on the dust vibrator to shake off any cement clinging to the dust collector bags. Otherwise, cement may become lodged in the bags, potentially causing a silo explosion.

If cement clogs the bags, the pressure inside the silo will exceed the safety valve's pressure, which will then immediately open, releasing the pressure.

Cement storage systems are typically equipped with a level measurement system that indicates the cement's position within the silo.

Related products

-

Quick View

MA-(2~8MM)×1800MM Steel Coil Slitting Line

Contact UsMA-(2~8MM)×1800MM Steel Coil Slitting Line is mainly composed by the following components : uncoiler, guiding device

-

Quick View

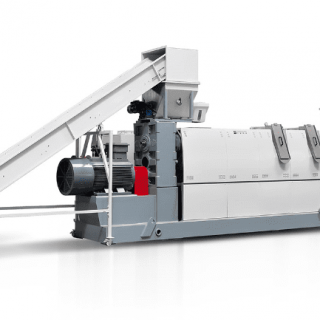

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

Quick View

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m -

Quick View

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

Reviews

There are no reviews yet.