Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

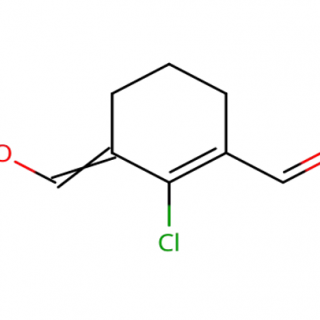

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

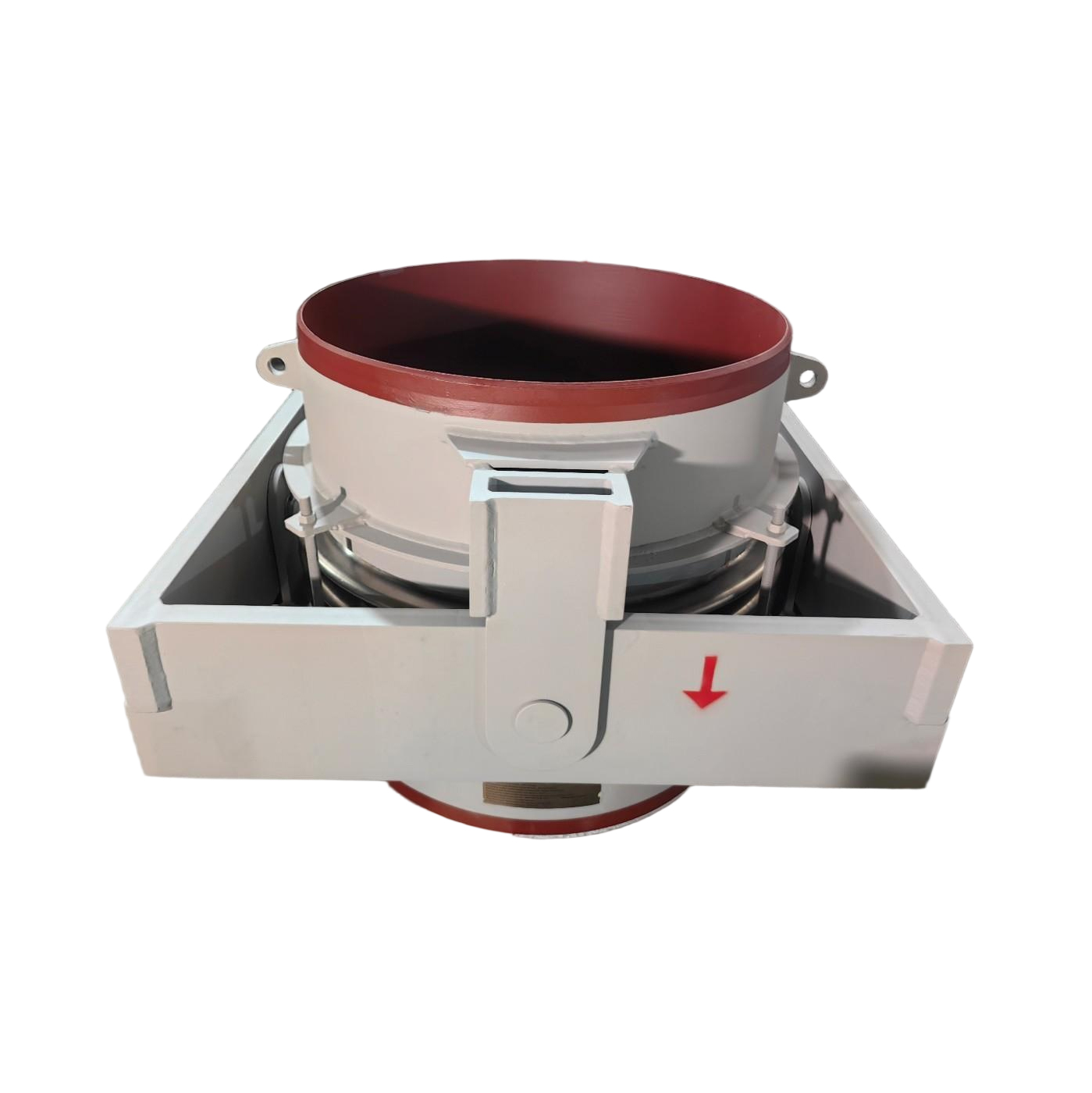

Universal hinged expansion joint

It consists of a bellows and structural parts such as hinge plates,universal rings and vertical plates, which absorb angular displacement in any planes and sustain the pressure thrust of the bellows

Universal hinged expansion joint-It consists of a bellows and structural parts such as pins,

hinge plates,universal rings and vertical plates, which can absorb angular

displacement in any planes and can sustain the pressure thrust of the

bellows;

Specification: DN50-DN5000

Working pressure: 0.25-2.5Mpa

Related products

-

Quick View

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

Quick View

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

-

Quick View

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

Reviews

There are no reviews yet.