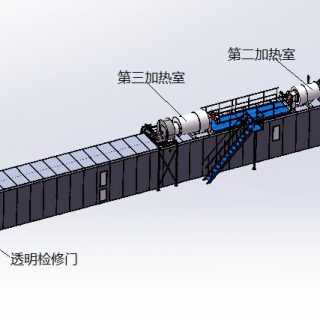

Solid-liquid incinerator project for Ningxia

This project is a 10,000 tons/year hazardous waste incineration device for Ningxia, which is used for incineration and treatment of hazardous waste produced by our factory.

Automatic feeding system — automatic feeding system — Rotary kiln — liquid waste furnace — secondary combustion chamber — SNCR denitration system — Waste heat steam boiler — rapid cooling deacidification tower — dry spray tower (lime, activated carbon jet) — cloth bag dust collector — Induced draft fan — SCR denitration system — spray tower — packing spray tower — wet electric dust collector — smoke fontanel — discharge

Related products

-

Quick View

PP Rainwater Module 35T(Black)

Contact UsPP plastic modules are injection-molded from polypropylene. They can be interconnected to form an underground water storage tank.

-

Quick View

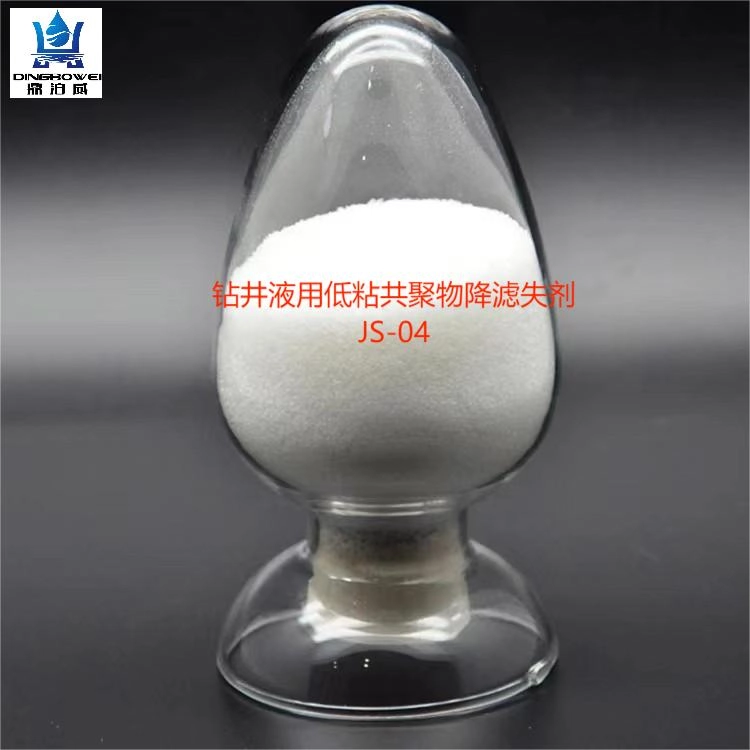

JS-04 Low Viscosity Polymer Filtration Reducer

Contact UsJS-04 is the polymer fluid loss additive of amphoteric and temperature and salt resistance using redox initiator system by AM, AA, AMPS, SA and DMDAAC with water as solvent. DF-03 can reduce the filtration loss, improve the mud cake quality, has good ability of high temperature resistance, salt and calcium contamination resistance. DF-03 has low viscosity to mud system due to narrow molecular weight scale. It is especially suitable for freshwater, saltwater, seawater drilling and completion fluids. The recommend dosage is 3.0 – 7.0ppb.

-

Quick View

LCTW Dynamic pass box

Contact UsThe self-cleaning transfer window allows for the transfer of materials, utensils, and other items under Class A environmental protection. Items are self-cleaned within the window before entering areas of higher cleanliness. The self-cleaning transfer window is equipped with an ultraviolet sterilization lamp and can also be fitted with a royal oxygen sterilization system according to user requirements.

-

Quick View

Metal sheet drying oven for can making

Contact UsThe oven is mainly used to dry the coating on the tin (or aluminum) sheet in the can making process. The entire line mainly consists of conveying, feeding devices, drying, cooling, and material collection and stacking.

Reviews

There are no reviews yet.