Category

Popular

-

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

1.5W 5.5V Customized Small Mini Round Circle Solar Panel Diameter 110mm Perc Monocrystalline Silicon Solar Cell PET Abrazine PCB Backsheet Red Black Wires Lightweight DIY Solar Products

-

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

2.5W 9V Mono Epoxy Resin Small Mini 173x132mm Solar Panel Power Output with Extend Wire DIY Solar Panel for Projects Factory Wholesale Solar Charger

-

CPE Stretching Film Line

CPE Stretching Film Line

-

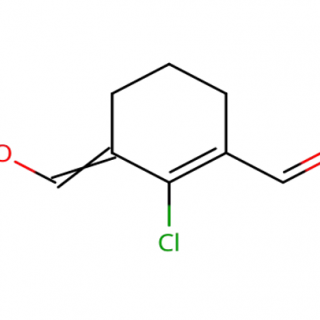

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

2-chloro-3-(hydroxyMethylene)cyclohex-1-enecarbaldehyde

-

WE67K-50/1500 Small CNC Press Brake

WE67K-50/1500 Small CNC Press Brake

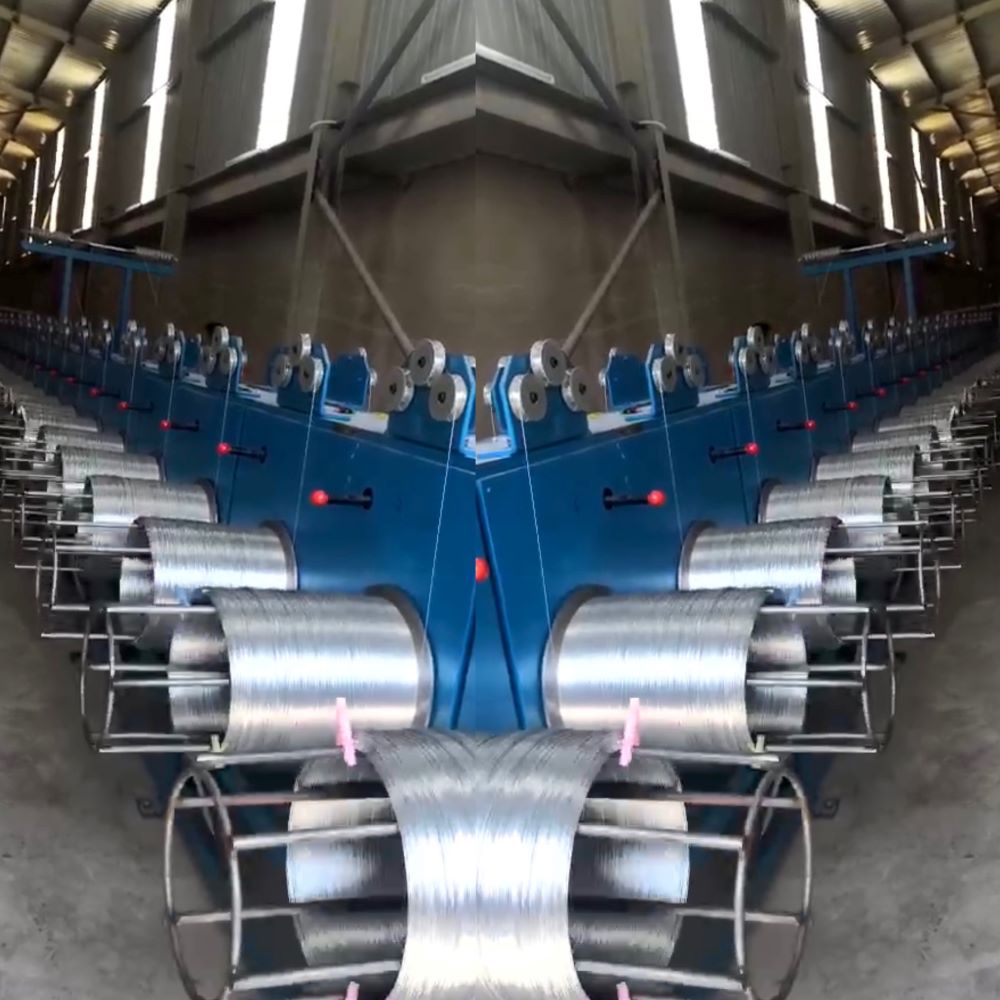

Galvanized Wire Machine

Products: Low ,medium and high carbon galvanizing steel wire, Diameter range: 0.7~1.5mm, 0.9~2.5mm, 3.0~5.0mm As clients requirement Coating Zinc weight range: 5~15 g/m2 ,15~35g/m2

Electric galvanizing design scheme for Low carbon steel wire

I、Design basis:

1、Products: low carbon galvanized steel wire

2、Raw material: Example -SAE1006, Q195 wire

3、Wire diameter: φ0.8—3.0mm

4、Steel wire strength: 350–450Mpa

5、Galvanized layer weight: 10g/m2, tolerance ±1g/m2

6、DV value: 80

7、Line number: 24 lines

8、Wire spacing: 25mm Spacing; Max width Total 2500mm;

9、Height of steel wire from the ground (elevation of steel wire travel): 950mm

10、Wiring method: straight in type

11、Line length: approximately 90 meters

12、Workshop length: straight in type

13、Usage voltage: According to customer requirements, our standard voltage is 380V

14、Output (minimum): > 16T/day (based on ø 1.2mm, 50m/min, 24 hours/day),

> 12T/day (based on ø 0.8mm, 90m/min, 24 hours/day)

According to the factory working efficiency: >75%

Note: This price is according to:

1.Uesd for: mesh wire, building wire, binding wire

2.Product Capacity: As machine normal design speed

3. Electric power resource: 440V, 50HZ.

|

Example galvanizing wire product capacity |

|||||

|

mm |

DV |

hours |

pcs |

efficiency |

Tons |

|

0.9 |

90 |

24 |

40 |

85~80% |

24.43~23 |

|

1.6 |

90 |

24 |

40 |

85~80% |

43.25~40.7 |

|

2 |

90 |

24 |

40 |

85~80% |

154.3~51 |

|

2.5 |

90 |

24 |

40 |

85~80% |

67.88~63.89 |

Process flow:

No.1. Pay-off bobbin→ Space 2.5 meters →No.2. Alkaline water washing (5m)→No. 3. Hydrochloric acid pickling (8.4m) →No.4. water washing (4m)→No.5. electro galvanizing (27m)→No.6. water washing (include hot water washing saponification 4m)→No.7. drying (4m)→Space 2.5 meters→No.8 wire collection take up machine

Acid mist purification tower:

To prevent acid gas leakage and environmental pollution caused by the accumulation of hydrogen gas in the pickling tank, a set of acid mist purification tower is equipped. The acid mist is absorbed and neutralized by the spray, and a small amount of hydrogen is discharged through the pipeline.

The take-up Machine: Horizontal coiler ,Block collecting wire

Adopts a 450mm horizontal take-up machine, with a take-up wire collecting in coiler rack ;The take-up machine is driven by a chain wheel, with 2-sets 11kw take-up motors equipped with frequency converters and reducers. Each single disc is equipped with a full disc and a manual clutch for automatic parking.

Related products

-

Quick View

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

Quick View

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

-

Quick View

FSH-FMI2020-B Standard Single/Double Channel Fluid Injection

Contact UsFSH – FMI2020 – B standard series of high-precision fluid dispensing / refilling system consists of a digital control box, stepper motor and one to two high precision rotary ceramic pump modules driven by step motor.

Reviews

There are no reviews yet.