JZJ2B(S)W Series Roots Vacuum Pump Unit

The JZJ2B(S)W series Roots-liquid ring closed-loop vacuum unit utilizes a ZJ Roots pump as the main pump and a 2BV/2BE/2SK liquid ring vacuum pump or a Roots-liquid ring vacuum unit.

JZJ2B(S)W Series Roots Vacuum Pump Unit

I. Applications

The JZJ2B(S)W series Roots-liquid ring closed-loop vacuum unit utilizes a ZJ

Roots pump as the main pump and a 2BV/2BE/2SK liquid ring vacuum pump or a

Roots-liquid ring vacuum unit as the backing pump. It can be used not only to

extract general gases but also gases containing moisture and small amounts of

dust. Compared to conventional mechanical vacuum pumps, it is resistant to oil

contamination, moisture, and fine dust. It is an ideal vacuum extraction system

for drying, dehydration, and vacuum degassing in industries such as textiles,

food, chemicals, and pharmaceuticals. II. Features

1. The JZJ2B(S)W series Roots liquid ring vacuum units utilize the highly

efficient and energy-efficient 2BV liquid ring vacuum pump as their backing

pump. Consequently, the JZJ2B series Roots liquid ring vacuum units offer

advantages over the JZJ2SW series Roots liquid ring vacuum units, including

higher efficiency, compact structure, zero leakage (the 2BV series utilizes a

standard mechanical seal design, unlike the 2SK series' packing seal), corrosion

resistance (the 2BV series utilizes a stainless steel impeller), and a higher

level of protection.

2. The backing pump for Roots liquid ring vacuum units typically uses water

as the working fluid, but can also operate with organic solvents (such as

methanol, ethanol, xylene, and acetone) or other liquids. Using the backing pump

as a closed-loop system significantly reduces environmental pollution and

significantly improves organic solvent recovery. The ultimate vacuum level is

determined by the saturated vapor pressure of the working fluid.

Main Performance Parameters

|

Unit Model |

Pump Model |

Pumping Speed L/s |

Maximum Suction Inlet Pressure Pa |

Ultimate Pressure Pa (Absolute) |

Total Power KW |

||

|

Main Pump |

Foreline Pump |

Water Ring Unit |

Oil Ring Unit |

||||

|

JZJ2BW30-1 |

ZJ30 |

2BV5110 |

30 |

12000 |

267 |

80 |

4.75 |

|

JZJ2BW70-2 |

ZJ70 |

2BV5110 |

70 |

6000 |

5.5 |

||

|

JZJ2BW70-1 |

ZJ70 |

2BV5111 |

70 |

12000 |

7 |

||

|

JZJ2BW150-2A |

ZJ150 |

2BV5111 |

150 |

6000 |

8.5 |

||

|

JZJ2BW150-2B |

ZJ150 |

2BV5121 |

150 |

8000 |

10.5 |

||

|

JZJ2BW150-1 |

ZJ150 |

2BV5131 |

150 |

10000 |

14 |

||

|

JZJ2BW300-2A |

ZJ300 |

2BV5131 |

300 |

4000 |

15 |

||

|

JZJ2BW300-2B |

ZJ300 |

2BV5161 |

300 |

5000 |

19 |

||

|

JZJ2BW30-2.1 |

ZJ30 |

ZJ15, 2BV2061 |

30 |

8000 |

25 |

0.8 |

2.8 |

|

JZJ2BW70-2.1 |

ZJ70 |

ZJ30, 2BV5110 |

70 |

6000 |

6.25 |

||

|

JZJ2BW150-2.1 |

ZJ150 |

ZJ70, 2BV5111 |

150 |

6000 |

10 |

||

|

JZJ2BW150-4.1 |

ZJ150 |

ZJ30, 2BV5110 |

150 |

3000 |

7.75 |

||

|

JZJ2BW300-2.1 |

ZJ300 |

ZJ150, 2BV5131 |

300 |

5000 |

18 |

||

|

JZJ2BW300-2.2 |

ZJ300 |

ZJ150, 2BV5121 |

300 |

4000 |

14.5 |

||

|

JZJ2BW300-4.1 |

ZJ300 |

ZJ70, 2BV5111 |

300 |

2000 |

11 |

||

|

JZJ2BW600-4.1 |

ZJ600 |

ZJ150, 2BV5131 |

600 |

1500 |

19.5 |

||

|

JZJ2BW600-2.2 |

ZJ600 |

ZJ300, 2BV5161 |

600 |

2000 |

24.5 |

||

|

JZJ2BW1200-4.2 |

ZJ1200 |

ZJ300, 2BV5161 |

1200 |

1000 |

30 |

||

|

JZJ2BW30-2.1.1 |

ZJ30 |

ZJ15, ZJ15, 2BV2061 |

30 |

8000 |

0.5 |

0.05 |

3.35 |

|

JZJ2BW70-2.2.1 |

ZJ70 |

ZJ30, ZJ15, 2BV2061 |

70 |

4000 |

4.3 |

||

|

JZJ2BW70-2.1.1 |

ZJ70 |

ZJ30, ZJ30, 2BV5110 |

70 |

6000 |

7 |

||

|

JZJ2BW150-2.2.1 |

ZJ150 |

ZJ70, ZJ30, 2BV5110 |

150 |

3000 |

9.25 |

||

|

JZJ2BW300-2.2.1 |

ZJ300 |

ZJ150, ZJ70, 2BV5111 |

300 |

3000 |

14 |

||

|

JZJ2BW300-4.2.1 |

ZJ300 |

ZJ70, ZJ30, 2BV5110 |

300 |

1200 |

10.25 |

||

|

JZJ2BW600-2.2.1 |

ZJ600 |

ZJ300, ZJ150, 2BV5131 |

600 |

2500 |

23.5 |

||

|

JZJ2BW600-4.2.1 |

ZJ600 |

ZJ150, ZJ70, 2BV5111 |

600 |

1200 |

15.5 |

||

|

JZJ2BW1200-4.2.1 |

ZJ1200 |

ZJ300, ZJ150, 2BV5131 |

1200 |

1000 |

29 |

||

|

Unit Model |

Pump Model |

Pumping Speed L/s |

Maximum Suction Pressure Pa |

Ultimate Pressure Pa (Absolute) |

Total Power KW |

||

|

Water Ring Unit |

Oil Ring Unit |

||||||

|

Main Pump |

Foreline Pump |

||||||

|

JZJ2SW30-1 |

ZJ30 |

2SK-1.5 |

30 |

12000 |

267 |

80 |

4.75 |

|

JZJ2SW70-2 |

ZJ70 |

2SK-1.5 |

70 |

6000 |

5.5 |

||

|

JZJ2SW70-1 |

ZJ70 |

2SK-3 |

70 |

10000 |

9 |

||

|

JZJ2SW150-2 |

ZJ150 |

2SK-3 |

150 |

6000 |

10.5 |

||

|

JZJ2SW150-1 |

ZJ150 |

2SK-6 |

150 |

10000 |

18 |

||

|

JZJ2SW300-2 |

ZJ300 |

2SK-6 |

300 |

4000 |

19 |

||

|

JZJ2SW300-1 |

ZJ300 |

2SK-12 |

300 |

8000 |

26 |

||

|

JZJ2SW600-2A |

ZJ600 |

2SK-12 |

600 |

4000 |

27.5 |

||

|

JZJ2SW600-2B |

ZJ600 |

2SK-20 |

600 |

7000 |

42.5 |

||

|

JZJ2SW70-2.1 |

ZJ70 |

ZJ30, 2SK-1.5 |

70 |

6000 |

25 |

0.8 |

6.25 |

|

JZJ2SW150-2.1 |

ZJ150 |

ZJ70, 2SK-3 |

150 |

6000 |

12 |

||

|

JZJ2SW300-2.1 |

ZJ300 |

ZJ150, 2SK-6 |

300 |

5000 |

twenty two |

||

|

JZJ2SW600-2.1 |

ZJ600 |

ZJ300, 2SK-12 |

600 |

4000 |

31.5 |

||

|

JZJ2SW150-4.1 |

ZJ150 |

ZJ30, 2SK-1.5 |

150 |

3000 |

7.75 |

||

|

JZJ2SW300-4.1 |

ZJ300 |

ZJ70, 2SK-3 |

300 |

2000 |

13 |

||

|

JZJ2SW600-4.1 |

ZJ600 |

ZJ150, 2SK-6 |

600 |

1500 |

23.5 |

||

|

JZJ2SW1200-4.1 |

ZJ1200 |

ZJ300, 2SK-12 |

1200 |

1000 |

37 |

||

|

JZJ2SW300-4.2.1 |

ZJ300 |

ZJ70, ZJ30, 2SK-1.5 |

300 |

1200 |

0.5 |

0.05 |

10.25 |

|

JZJ2SW600-4.2.1 |

ZJ600 |

ZJ150, ZJ70, 2SK-3 |

600 |

1200 |

17.5 |

||

|

JZJ2SW1200-4.2.1 |

ZJ1200 |

ZJ300, ZJ150, 2SK-6 |

1200 |

1000 |

33 |

||

|

JZJ2SW2500-4.2.1 |

ZJ2500 |

ZJ600, ZJ300, 2SK-12 |

2500 |

1000 |

53.5 |

||

Related products

-

Quick View

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

-

Quick View

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

Quick View

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

Quick View

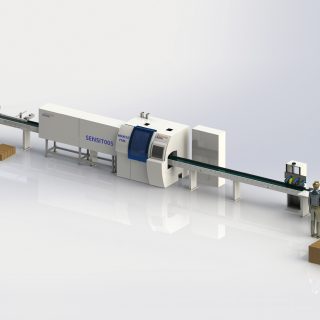

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line.

Reviews

There are no reviews yet.